Sanitary Check Valves: A Selection Guide

Whether it be in the food, beverage, pharmaceutical, or other industries, an effective fluid system requires sanitary check valves with the right material construction, style, and valve features for each specific application. Learn more about the different material and style options available so you choose the right products for your system.

Selecting the Best Sanitary Check Valve for Your Application

Choosing the right materials and valve style is just as important as selecting the correct size. Your needs may vary based on factors like:

- Industry standards

- Piping configuration and drainage needs

- Fluid compatibility with chemicals in the system

- Operational temperatures

- Pressure rating

- Clean-in-Place

The team at DFT® can help you choose the right product based on your application’s unique specifications, and this overview can help you start comparing different options.

Industries That Use Sanitary Check Valves

Check valves appear in many industries that work with pressurized fluids. They most frequently appear in facilities involving:

- Food and beverage processing

- Pharmaceutical manufacturing

- Chemical processing

In these industries and others, sanitary check valves play roles in controlling fluid movement in:

- Condensate lines

- Evaporators

- Gas purges

>> Download Our eBook on Using Sanitary Valves in Food, Beverage, and Life Science Industries

Our In-Line Sanitary Check Valves: DSV®

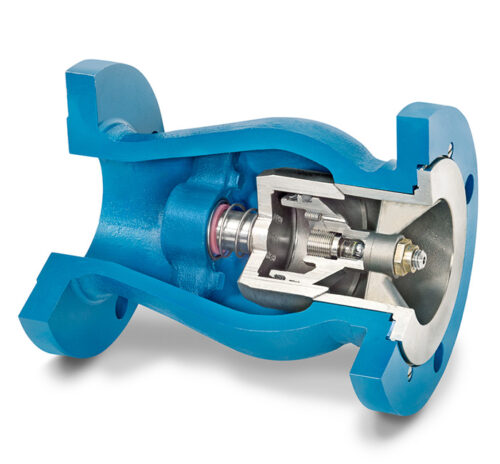

DFT® offers a full range of sanitary check valves for a diverse array of industrial applications. Our DSV® in-line, spring-assisted check valves meet 3A standard 58-02 and are designed for industries that abide by strict sanitary codes.

DSV® valves have a Clean-in-Place design, featuring a 316L stainless steel body and seat. The DSV® is fastened using a quick-release clamp and elastomeric body seal. To provide superior shutoff capability, each disc and seat is lapped. Standard DSV® valves have a 32 Ra internal surface finish, with an optional a 15 Ra internal finish available. The design has an edge-guided and center-guided disc for reliable performance.

DSV® valves come in many sizes to meet the needs of most piping arrangements. We manufacture valves from 0.5” to 4” line sizes, and our products can meet vertical or horizontal specifications as required.

Explore Our Sanitary Check Valve Catalog

Sanitary Check Valve Style Options – Vertical or Horizontal

There are two main styles of DFT® sanitary check valves: horizontal and vertical. Select the most compatible option to ensure optimal system performance.

Horizontal

DSV® Horizontal style sanitary valves are built for horizontal lines that need a self-draining valve capable of providing complete drainage. Horizontal valves prevent fluid pooling and help make cleaning and maintenance tasks easier.

Vertical

DSV® Vertical style sanitary valves can be used on both vertical flow up and vertical flow down lines. Additionally, they can be used in horizontal lines that do not require self-draining.

Gasket Body Seal Materials

Below is a brief list of common body seal materials available for use in sanitary check valves:

Please note, for more details on these and other body seal gaskets, contact DFT® or visit the specific product company website for the latest specification sheet.

Case Study: DSV® Check Valve Delivers Reliable Performance for Pharmaceutical Customer

Case Study: DSV® Check Valve Delivers Reliable Performance for Pharmaceutical Customer

To illustrate the success of our DSV® sanitary check valves, consider this case study. One of our pharmaceutical customers needed a waste drain check valve that featured sanitary connections, could be steam-cleaned in place, had tight shut-off, and had low cracking pressures. Our 2” DSV® check valve met all of their requirements while preventing flow reversal, a critical requirement in the pharmaceutical industry. This sanitary check valve has remained in operation for this client since 2009.

Contact Our Experts for Sanitary Check Valve Solutions

The right sanitary check valves make all the difference in the performance and efficiency of your fluid systems—as well as supporting compliance with applicable regulations. At DFT®, we can help you select the best sanitary check valve product for your facility’s needs. Contact us today to learn more about our valve products, or request a quote to start your order.