Nozzle Check Valves

There are innumerable fast-reversing fluid flow applications that require protection against surges or backflow, including axial flow scenarios.

DFT® has been a world renowned manufacturer of in-line “non-slam” check valves since 1943. We offer a diverse line of reliable check valves, including a family of nozzle check valves that are an ideal backflow protection solution for virtually any application.

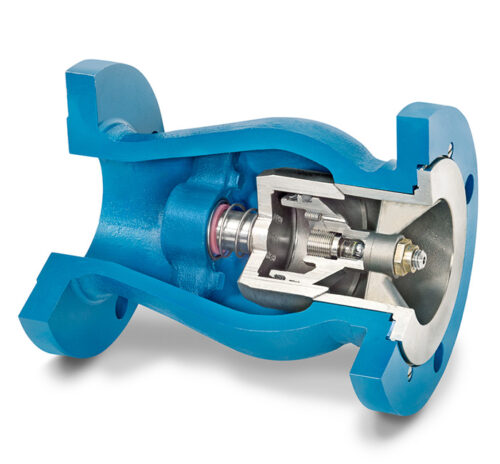

Nozzle Check Valve Basics

Nozzle check valves are designed specifically for scenarios in which a fluid, gas, or slurry is pumped in a low pressure or otherwise intermittent flow. In particular, they are meant to close quickly and quietly during low pressure and no-flow periods, and can be used to reliably prevent the liquid, gas, or slurry from flowing in the reverse direction.

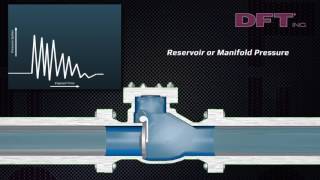

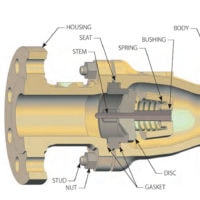

In nozzle check valves, the shutoff mechanism is a disc, which is held against the seat by an internal spring. When the pressure of the fluid, gas, or slurry against the disc at the inlet overpowers the closing force of the spring, the spring compresses and the fluid, gas, or slurry flows freely. When the fluid flow slows or stops, the spring automatically closes the valve.

Because of its unique nature, this type of valve offers a number of benefits:

- Quick and dynamic responses to changes in flow pressure and velocity

- Pressure loss minimization

- Minimization or elimination of water hammer, and its damaging effects

- Elimination of valve chatter in low flow conditions

- Protection for pumping and rotating equipment from reversed flows

- Zero leakage performance when compared to other check valve types

By their nature, nozzle check valves are useful in a large variety of scenarios and settings. They are as essential for reducing water hammer in residential plumbing systems as they are for preventing backflow in heavy industrial applications, such as chemical processing, cooling towers, mine dewatering, and many more applications.

Nozzle check valves have distinguished themselves particularly well in chemical and petroleum processing plants. In these scenarios, nozzle check valves have proven highly effective at stopping backflow while providing tight shut off performance. For mixing processes that require components to remain at precise percentages, such as ethanol-additive blending, backflow protection is extremely important.

DFT®’s Proprietary Nozzle Check Valves

Using a state-of-the-art design and test simulation software, DFT® offers a

Both internally and externally, DFT® nozzle check valves feature a number of key differences than those of our competitors:

- Body diameter — We have found that nozzle check valves with bodies notably larger in diameter than their inlets display the best flow characteristics.

- Disc design — The disc faces for all of our nozzle check valves are designed to maximize hydrodynamic efficiency and minimize pressure loss.

- Soft seat — All nozzle check valves from DFT® feature soft seat, a specially designed and sourced O-ring installed in the seat of the valve. Soft seat drastically reduces reverse flow leakage and aids the quiet closing of the valve.

- Single spring — DFT® nozzle check valves use only one spring designed for a million cycle life time in the body, as opposed to most other companies, which use multiple springs. Minimizing the number of springs reduces the potential for failure.

Employing more than 70 years of valve design and manufacturing experience, along with high-tech design and testing software, DFT® manufactures a line of five high-quality nozzle check valves — Excalibur, WLC, ALC, PDC, and GLC.

To learn more about our nozzle check valves and how to implement them in your system for maximum effect, contact us today.