Natural Gas Success Story

Facility: Major Gulf Coast Petrochemical Plant

Application Problem: Natural Gas/Methane OEM Turbo-Expander Vertical Installation

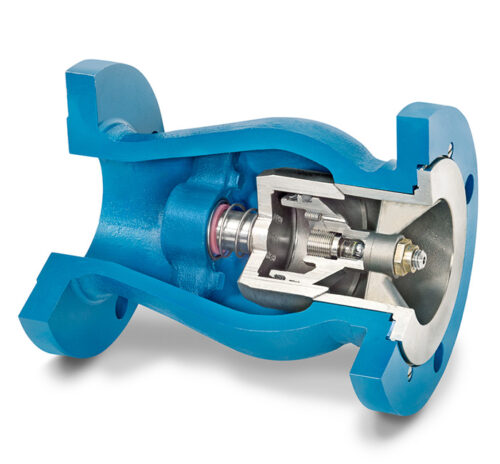

Solution: DFT® Model GLC® Check Valve

Solution: DFT® Model GLC® Check Valve

Success Since: 1999

Challenge: A Major Gulf Coast Petrochemical Plant was experiencing swing check valve failures. The plant was part of an OEM turbo-expander that originally installed swing check valves. These original valves had failed quickly due to low flow and excessive cycling/pounding. DFT was called to find a solution to their check valve problem.

Solution: The DFT® model GLC® Check Valves were custom-sized for this application to minimize excessive cycling and chattering problems that were seen with the previously installed swing-type check valves.

Installed were 16”, 18” and 20” DFT GLCs with a carbon steel body and stainless steel trim.

DFT® Model GLC Features:

- 2” to 42” line size*

- ASME class 150 to 2500

- RF & RTJ flanged ends

- “Short” face-to-face dimensions

- Standard Body Materials:

- A216 WCB carbon steel

- A351 CF8M stainless steel

- Stainless steel trim

- Center-guided/dual-guided stem

- Spring assisted silent closing, non-slam

- Tight shutoff – lapped disc & seat

- Horizontal or vertical installation

- Protected spring

- *Consult DFT for larger sizes

For a downloadable pdf version, click here.

For more information on Industry success stories, click here.