Category Archive: Check Valves

Threaded Check Valves Guide

Threaded check valves are a type of valve that features either internal or external threaded end connections. The term “threaded” refers to the valve end connection, which is the component of the valve that connects with the piping system. This type of valve is typically easy to install and performs very well in applications with various pressures and temperatures. Most often, threaded valves are four inches or under. These components are available with either male or female connections and can be tapered or straight. Tapered threaded valves (NPT ends) will provide a direct seal, while straight threaded valves (NPS ends) will require auxiliary components to provide a seal.

Uses for Threaded Valves

Threaded valves are widely found in applications with stable pressures and temperatures. They can be used in liquid, gas, or steam applications. Industries that commonly utilize threaded valves include:

- Boiler

- Food and beverage

- Power generation

- Pharmaceutical

- Municipal

- Pulp and paper

- Chemical processing

- Water treatment

- Mining

- Test laboratories

- Textiles

- Primary metals

- Gas transmission

- Petroleum production and refining

- Building maintenance

Applications

Threaded valves can be found throughout all industries but are common within the petrochemical industry and can often be found in refineries. They are also a popular choice for boiler and steam applications. In these cases, the environment will typically feature very high temperatures coupled with low pressures.

It is also possible to use threaded valves in applications related to gas or oil production. Unlike steam and petrochemical applications, gas and oil production will feature extremely high pressures, prolonged opening and closing times, and harsh environmental conditions.

Factors to Consider Choosing the Right Threaded Valve

To protect the long-term performance of your piping system, it is important to choose the appropriate threaded valve. There are several factors to consider when making this decision. A significant consideration is the amount of pressure that the valve must withstand. For applications with high pressure, an externally threaded valve is the optimal choice, as it will have a thicker wall than an internally threaded valve.

It is also important to determine whether the valve must provide a direct seal. Applications that require a fluid-tight seal will generally necessitate the use of a tapered valve, as this will provide a seal without the need for any additional components. National Pipe Thread Tapered (NPT) valves are the U.S. standard for applications requiring tapered valves.

Factors to consider when choosing a threaded valve include:

- Temperature

- Pressure

- Tight seal (metal or soft seat)

- Size and weight

- Adherence to industry and plant standards

- Valve permanence

- Ease of installation

- Ease of removal

- Budget

- Inventory simplification

Threaded Check Valves from DFT Valves

Since 1943, we at DFT Inc. have been engineering and manufacturing world-class, in-line check valves for use in a wide array of industries, from petroleum refining to food and beverage.

Our check valves can be installed vertically or horizontally and play an integral role in steam condensate management systems. These systems help maintain high-quality steam, thus preventing the development of many issues within the pipe and valve. In particular, our line of SCV threaded check valves is ideally suited for use in steam condensate applications. These valves feature a range of qualities, including corrosion resistance and longevity, that ensure their high performance in applications of this type.

For over seven decades, our priority has been preventing threaded check valve failures. We are dedicated to providing our customers with threaded valves that are both sized appropriately and suited to the unique needs of each application. To learn more about our offerings, browse our Threaded Valves Catalogue or contact us today.

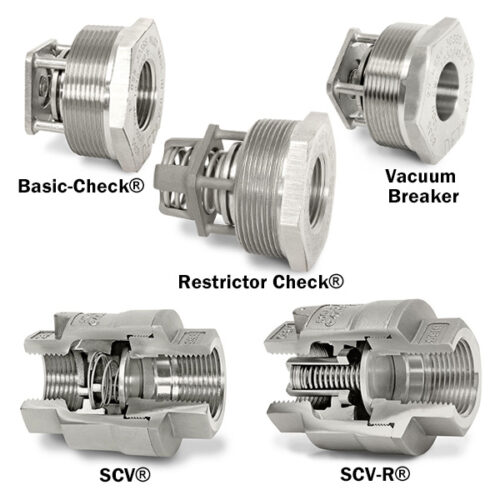

DFT Threaded Check Valves are available in the following types and sizes:

SCV Check Valves – 1/2” to 2” – 750 & 3600 CWP

SCV-R – ½” to 2” –

Basic Check – ¼” to 2 ½”

Restrictor Check – ¼” to 2 ½”

Vacuum breakers – 1”” to 4”

DFT®’s ALC® and WLC® Wafer Check Valves

Water hammer is a problem that can occur in piping systems that use pumps or valves to control liquid or steam flows. It is commonly caused by a sudden closure of a valve or shutdown of a pump and presents as a loud banging or knocking sound in the pipes. If the problem is severe enough, water hammer can cause damage to pumps, pipe ruptures, or broken gaskets or welds, creating a safety hazard for anyone in the vicinity.

To eliminate water hammer from your system, we first must understand the various harmful effects it can have and what solutions are available to resolve them.

The Harmful Effects of Water Hammer

Water hammer occurs when a fluid in motion suddenly stops or changes direction. The fluid sends a shockwave—called hydraulic shock—through the system, causing vibration or banging in the pipes immediately following shutoff.

Water hammer is an issue that can cause damage to your flow system and overall operation. The most common consequences are:

- Pump and flow system damage: Water hammer can cause pumps, valves, and other instruments to be damaged. Seals and gasketed joints can fail, and the integrity of welded joints and pipe walls can be compromised.

- Ruptured pipes: Local pipeline failure as a result of extreme pressure spikes can lead to complete rupture, which can be costly and time-consuming to repair.

- Accidents: Ruptured pipes can endanger maintenance staff and other employees. In some facilities, such accidents can put them at risk of electrocution, slips, and falls.

- Leaks: When pressure waves hit the pipes, they can damage connections, joints, and fittings, leading to leaks. These weak spots may go unnoticed or grow slowly over time, exposing surrounding equipment to potential damage.

- External property damage: The water from a ruptured pipe can cause external damage or corrosion to infrastructure and electrical devices.

- Unscheduled downtime: If a pipe ruptures or causes property damage, repairs can be lengthy. This can lead to lost production and other financial losses related to the repair.

Our Solution

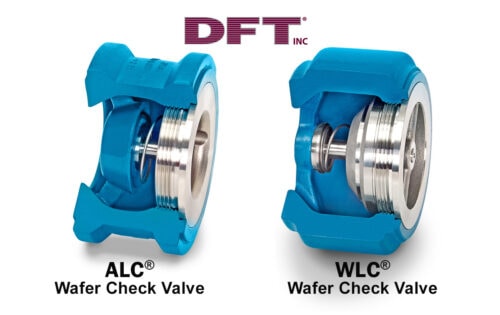

DFT® is a world-class manufacturer of check valves for a wide range of industries and applications. Our ALC® and WLC® are wafer-style check valves that help to prevent water hammer and reverse flow. They can be a direct replacement for failing double-door or dual-plate check valves. DFT® non-slam, spring-assisted, and center-guided check valves are designed to maximize the service life of your flow system.

The ALC® Wafer Check Valve is a compact, lightweight spring assisted valve with API 594 face-to-face dimensions that fit between mating flanges. The body is constructed from corrosion-resistant stainless steel and carbon steel, and it can be used in vertical or horizontal installations. Compatible with steam, gas, or liquid process flows, the ALC® check valve features spring-assisted silent closing.

The WLC® Wafer Check Valve is a lightweight, spring-assisted valve suitable for a wide range of pressures, temperatures, and fluids. With a carbon steel and stainless steel body, the WLC® features a protected Inconel spring and dual-guided stem. Optional body materials such as Alloy 20, Hastelloy®, Duplex SS, Titanium, and Inconel® 625 are available.

Benefits of Our ALC® and WLC® Wafer Check Valves

To eliminate water hammer and reverse flow from your industrial piping system, look no further than DFT®’s ALC® and WLC® Wafer Check Valves. These non-slam check valves do not rely on gravity or reverse flow for their closure. Instead, as the forward velocity of the fluid slows, the spring assist on the valve starts to close ahead of flow reversal. The DFT® spring-assisted operation ensures that the valve does not slam shut, thus preventing water hammer and its associated noise and damage. Here is an overview of the features and benefits of each product line.

ALC® Wafer Check Valves

- Available in sizes 2” to 24”, Class 150 & 300

- Meets API 594 face-to-face dimensions

- Center-guided

- Suitable for gas, liquid, or steam applications

- Can be installed vertically or horizontally

- Can be custom-sized to your application

- Low maintenance, long service life

- Tapped holes in the body to aid installation (only 10” or larger)

- Download the ALC Cut sheet

WLC® Wafer Check Valves

- Available in sizes 1” to 10”

- Class 600 & 900/1500 RF meets API 594 face-to-face

- Class 150 & 300 RF meets MSS 126 face-to-face dimensions

- Center & dual-guided stem

- Works with a wide range of temperature/pressure combinations and fluids

- Can be installed vertically or horizontally

- Can be custom-sized for your application

- Available for Severe Service (WLC® SS) and Boiler Feed (WLC® BF) severe duty applications

- Low maintenance, long service life

- Download the WLC Cut sheet

Prevent Water Hammer With DFT® Check Valves

For more than 75 years, DFT® has been solving our customers’ check valve issues, preventing check valve failures, and eliminating water hammer problems. We offer cost-effective rapid prototyping, engineering assistance, and fast production turnarounds. Instead of merely meeting line size, DFT® specializes in producing in-line check valves that meet our customers’ specific requirements. As an engineered valve manufacturer, we have the capability to size to the application and solve unique problems by making adjustments to our valves to suit your application.

DFT® can evaluate your valve sizing requirements and answer any questions you may have about our WLC® and ALC® valve product lines. Browse the ALC® and WLC® product pages, or contact us today.

Webinar Q&A: Hydrogen Production and the Role of Engineered Check Valves

As a follow-up to our November 2022 webinar, Hydrogen Production and the Role of Engineered Check Valves, we’re sharing the questions we received from the audience. The answers are provided by host Stephen O’Neill, Director of Sales and Marketing of DFT ® Inc. O’Neill, MBA, is a degreed Mechanical Engineer with 30 years of experience in the valve industry including check valves, control valves, pressure relief valves and pulse jet valves.

In our webinar, Stephen broke down what to know about hydrogen production, including what hydrogen is, how it’s produced, the different methods of storage and more. He also provided in-depth information on the right check valves to use for various hydrogen applications.

Hydrogen and the Role of Engineered Check Valves Webinar

If you missed the webinar, you can now view it on demand. Simply click this link.

Below, our knowledgeable host answers questions regarding engineered check valves to help you find the right type and fit for your hydrogen application.

Q: Are there any pipelines in the USA (or in the world) with hydrogen injection? If so, what is the percentage of hydrogen? Is any pipeline operator nearing the 15% hydrogen composition?

A: Hydrogen can be injected in Natural Gas pipelines, but only up to 15% of the mix. This can be done, but it is still in the pilot stages.

Excalibur® Silent Check Valve

Q: Can the Excalibur be used in temp around 113F to -50F?

A: Yes, the Excalibur can be used in temperatures ranging from 133F to -50F, but in order to function at -50F the valve must be made of stainless steel.

Q: Is there something specific of API6D that only applies to check valves & not generally also to ball valves?

A: This specification defines the requirements for the design, manufacturing, assembly, testing, and documentation of ball, check, gate, and plug valves for application in pipeline and piping systems for the petroleum and natural gas industries.

This specification is not applicable to subsea pipeline valves, as they are covered by a separate specification, API 6DSS.

This specification is applicable to valves for the following pressure ratings only: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, and Class 2500.

PDC® Silent Check Valve

Q: How many cycles per minute can the PDC valve handle?

A: The PDC does not cycle on and close when it is installed downstream from a reciprocating compressor. The PDC has a built-in pulse dampening chamber that is designed to remain in the open position even as the compressor cycles. The valve does not begin to close until the upstream pressure decreases and begins to approach the cracking pressure.

Q: Would the PDC valve be used in addition or in lieu of the check valves used in a diaphragm compressor?

A: A diaphragm compressor is a variant of the classic reciprocating compressor with backup and piston rings and rod seal. The compression of gas occurs by means of a flexible membrane, instead of an intake element. The back and forth moving membrane is driven by a rod and a crankshaft mechanism. These compressors have built in check valves as part of their assemblies. The PDC would not typically be used in this application.

Q: What is the “special cleaning” required with cryogenic check valves?

A: Special cleaning is required to clean cryogenic valves and piping. This cleaning process is designed to remove oils, grease, and fibers, which may interfere with your system’s functionality or present a flammability hazard depending on the service. After washing the valve’s component parts in a solvent cleaner, workers must inspect them for any residues the cleaning procedures may have missed. In most cases, the valves and pipes should not contain any assembly grease or oils, although there are some approved lubricants for oxygen service components that will not harm the system with their presence. Some customer specs may not allow for the presence of any lint or fibers within the valve. Even if some fiber is allowed, no system should contain fibers greater than 1/8” (3 mm) in length. In oxygen systems, the presence of lint can be quite problematic due to the risk of flammability. It is critical to thoroughly inspect all the components that go into the system to make sure they are free of any and all contaminants. Black light testing allows inspectors to easily identify lint, fibers, or other residue that needs to be removed.

Q: Do you do check valves where the downstream pressure could be intermittently as low as or close to vacuum? Is there some special feature you use for this type of application?

A: DFT makes special check valves for use in vacuum applications. These valves are called Vacuum Breaker Check Valves. These valves have cracking pressures that range from .6 to .15 PSI.

Q: What is the suggested type of check valve for low pressures? (20-40 bar, non-cryogenic)

A: DFT does not consider 20 to 40 bar as low pressure applications. DFT has a side variety of check valves that can handle these pressures. The choice of valve would depend on size, end connection and material requirements.

Q: If liquid hydrogen is needed to be compressed to at least 5,000 PSI, how is the PDC suitable at Class 1,500?

A: 5,000 PSIG exceeds the pressure of a 1500 Class valve. A 2500 Class (non-catalogue) valve would have to be used at these pressures.

Q: Is there a plan to manufacture valves less than 2″ size especially for high pressure hydrogen (>300 barg).

A: We do not offer a PDC in sizes lower than 2 inch, due to restrictions associated with internal components

Q: For Saltwater pump discharge applications, is 316SS internal material available?

A: Yes, 316 internals are available. However, DFT also offers valves made of Nickel Aluminum Bronze material for saltwater applications. NAB may be a better choice.

Q: Do your check valves open only due to flow increase or delta P, or both?

A: DFT check valves are designed to open upon increased upstream pressure and/or decreased downstream pressure. Either condition can result in the .5 cracking pressure. Cracking pressure refers to the inlet pressure level at which the first sign of flow is present. It can also be described as a measure of the pressure differential between the inlet and outlet ports of the valve when flow is initially detected.

Q: Is H2 already used for running vehicles?

A: Yes, but the number is very limited. Hydrogen fueled vehicles require Hydrogen fueling stations. Most of the Hydrogen fueling stations in the US are in California. However, more are planned in other states including Texas. However, there are more than 20,000 forklift trucks that operate on hydrogen fuel cells in the US.

Q: For the reciprocating application, I think you mentioned a spring designed for 1,000,000 cycles. Does that spring cycle with every compressor piston stroke? If so, 1,000,000 cycles is not very long.

A: The PDC does not cycle on and close when it is installed downstream from a reciprocating compressor. The PDC has a built-in pulse dampening chamber that is designed to remain in the open position even as the compressor cycles. The valve does not begin to close until the upstream pressure decreases and begins to approach the cracking pressure.

Q: How do you minimize the back pressure that can be created by the check-valve on upstream equipment?

A: The way to minimize the potential for upstream backpressure is to install springs with low cracking pressure. A spring with a .5 PSIG cracking pressure would result in the release of any upstream backpressure that exceeded the .5 PSIG cracking pressure.

Q: Understanding that the PDC check valve is made for gas, what are the impact of particulates within the gas on the function of the valve (sensitivity to solids carried through)?

A: Particulate interfering with the operation of a PDC pulse dampening check valve is not something that we typically experience. However, if particulate is present in the flow stream and it is present is sufficient volume, it would have the potential to affect the operation of the pulse dampening chamber within the PDC. Scrubbers or separators would typically be installed in gas flow streams to remove such partials before they reach compressors or check valves.

Q: Is cracking a pressure and pressure loss related?

A: Cracking pressure refers to the inlet pressure level at which the first sign of flow is present. It can also be described as a measure of the pressure differential between the inlet and outlet ports of the valve when flow is initially detected. So, the answer is yes. If there is a loss of pressure on the downstream side of the check valve that results in a differential pressure that exceeds the cracking pressure, the valve will open and begin to flow.

For more than 75 years, DFT® Inc. has helped customers find and install the right check valves for their unique applications. To learn more about our valves, and how we can assist you, contact us directly.

Common Problems in Steam & Steam Condensate Systems

Steam plays an important role in just about every industrial segment we can think of. Chemical processing, mining, petroleum production and refining, power generation, Pulp and Paper, and textile, are all just some of the industries that use steam every day to do what they do. Maintaining high-quality Steam carries a number of benefits including the prevention of a range of piping and valve issues. Proper system designs are inherently lower in maintenance costs. Recovering steam condensate saves the user money and can also be the source of low-pressure steam that can be used in some other part of the process.

Steam condensate issues are numerous. Many steam maintenance problems can be traced back to inadequate or improper condensate removal from the system. Other factors like low steam quality, unsuitable equipment and components, poor piping practices, undersized or oversized pipes and valves, as well all play a role in some of the issues that we see in Steam condensate systems. Those issues can be corrosion, reverse flow where we don’t want it, and steam condensation flashing into steam. Condensate flashing can have several different problems associated with it, all by itself.

Corrosion

A common concern in Steam condensate systems is corrosion. Particularly important when condensate is allowed to accumulate and sit stagnant within the system. Left untreated, over time the corrosion can lead to system contamination, valve malfunction, the bursting of pipes, and many other problems. Any of these events can lead to costly system shutdowns and huge emergency repair costs.

Pressure Spikes

Pressure spikes are another common concern. There are three different pressure spike scenarios that can occur in a piping system. The first occurs in liquid-only systems, these pressure spikes can be caused by valves closing suddenly or pumps shutting down suddenly. In steam systems, condensate can accumulate and then flash to steam. As the steam expands to a vapor its volume increases by five to six hundred times. The third and most dangerous form of water hammer also happens in Steam systems and is commonly called condensate-induced water hammer. This is when the pooled condensate is being pushed by high-velocity steam traveling in the pipe. When the steam builds up a “wavefront” in the pooled condensate, a flashing of the liquid to vapor will have dramatic and catastrophic when it pushes a slug of water into an elbow or other constriction at velocities in the hundreds of feet per second.

Considering Line Sizing & Handling Condensate

There are a number of factors that should be carefully considered when designing or redesigning a steam condensate system. These include line sizing. Always make sure that the pipes themselves are properly sized. This can be a leading cause of condensate collection. The location of condensate return lines in relation to other pieces of Process Equipment is also very important. Insulation methods and techniques are particularly important to prevent flashing. Look for low points where condensate can accumulate. The final point is to consider the type or quality of the valve used. Not all check valves will do an adequate job in handling condensate.

Check valves can be a very important part of steam processes or condensate processes in general. It is not always possible to use off-the-shelf check valves for the applications for check valves in a steam or a condensate system. Often times low cracking pressure check valves are required. Screwed end (NPT) check valves are quite common in these applications for low-pressure condensate but also flanged style and wafer style check valves can be used. Generally, they need this low cracking pressure characteristic for use in condensate lines. In normal steam lines or hot water lines, standard cracking pressures may suffice but there may be other special modifications needed to a standard valve to get the best performance out of valves in those applications as well.

In-Line Check Valves from DFT®, Inc.

DFT Inc. has been designing and Manufacturing world-class in-line check valves since 1943. When sized properly for the system requirements high-quality check valves serve as integral and critical component parts in your Steam condensate Management System. One of the most popular valves we sell into steam condensate is the SCV check valve. This valve style coupled with some simple modifications for low cracking pressures performs exceptionally well in many steam condensate lines. Find out more about Steam and Steam Condensate by viewing the full webinar here: https://industrial.dft-valves.com/lp-steam-condensate-webinar

Having problems? We suggest that you contact one of our valve experts at DFT with your problems and the specific issues that concern you. https://industrial.dft-valves.com/contact-dft-dft-inc

Valves for the Mining Industry

The mining and mineral sector needs robust processing systems that can meet the harsh chemical, pressure, and temperature demands of the industry. Any leaks at a mining facility could result in environmental damage coupled with penalties and fines. To reduce costly and unscheduled downtime, systems and all components must function consistently and reliably, minimizing equipment damage and hazardous working conditions. Specialized valves within these processing systems, such as check valves, help ensure consistent movement and direction of fluid in numerous mining applications.

Check Valves

One of the least thought about, but most crucial types of valves in a mining operation is the check valve. Often these applications consist of both vertical and horizontal piping orientations. Check valves ensure the one-way flow of fluid throughout a piping system and protect pumps and compressors from backflow. They also rely on a tight seal to stop any reverse flow leakage. This functionality is crucial for mining operations, which need to provide a continuous supply of raw materials and processed fluids.

Check valves must be resistant to harsh substances despite their chemical properties, pH levels, temperatures, or pressures to prevent corrosion and overall wear. With a high-quality check valve, companies can efficiently maintain a controlled flow of fluid that doesn’t jeopardize production standards or cause downtime to mining equipment. Combined with a regular maintenance program, placing check valves throughout your piping system can reduce processing costs and downtime otherwise resulting from equipment strain, breakdowns, and component replacements.

Applications

Check valves are essential in both above- and below-ground applications for mining and processing materials. Some of the most common applications for check valves in the industry include:

- Autoclaving. High-quality alloy check valves can be used to prevent the reverse flow of fluid in autoclaving operations requiring Class V shutoff capabilities.

- Extraction processes. For above-ground extraction procedures, solvent extraction (SX) plants and pregnant leach solutions (PLS) processes utilize check valves. In SX plants, check valves are located at the pump discharge point for managing aqueous leach and organic fluids to prevent backflow and water hammer. These valves also function at the pump discharge stage in PLS procedures, but they can also stop reverse flow within a system.

- Mine dewatering. Dewatering processes use pumps to lower the water table near a mining site or quarry. The pumps that manage the dewatering in mining need robust check valves that can function well in vertical or horizontal orientations to guard against water hammer and keep the removed water flowing away from the site.

- Pipelines. Check valves maintain the one-way flow of water to and from mining locations, regardless of piping distance, orientation, or changes in elevation and height. They also protect valuable pumps from reverse flow and prevent water hammer.

- Pump isolation and discharge. Check valves prevent backflow and mitigate the risk of pump damage throughout discharge.

Flanged & Wafer Check Valves From DFT® Inc.

As an engineered valve company, DFT wafer and flanged check valve varieties meet the needs of the mining industry. Our robust WLC® and ALC® wafer check valves can handle a wide range of substance types, pressures, and temperatures for use throughout mining and refining processes. Each valve has a spring-assisted, non-slam mechanism to prevent backflow and seal tightly shut. The WLC® is available in sizes 1″-10″ and classes 150-1500 and features a center-guided design for superior performance and reliability. The ALC® wafer check valve is available in sizes 2″-24″ and in classes 150 and 300. Each of the wafer check valves has minimal leak paths and is compact, fitting between joining flanges in vertical as well as horizontal installations.

DFT® also offers a line of flanged check valves. Our Excalibur® Silent Check Valve series is another low-maintenance solution for ensuring a consistent, one-way flow of fluid through a processing system. The Excalibur® series includes an extensive range of options to meet different size requirements, pressure and temperature ratings, and material standards for best fit in most systems in the mining industry. Each valve has an in-line, dual-guided, and spring-assisted design so your facility can rely on its consistent operation. Flanged valves feature a simple, well-constructed design consisting of body, gasket, spring, seat, and disc (with stem and guide bushing) components. Excaliburs are designed to meet the ASME B16.10 face-to-face standard.

For over 75 years, DFT® has been assisting clients with their in-line check valve requirements with a focus on superior customer service. Contact us today to learn more about our specialty valves or to request a quote for pricing details.