Category Archive: Check Valves

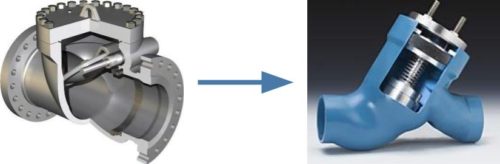

Why You Should Replace Your Swing Check Valve With a Silent Check Valve

Used to restrict fluid flow to a certain direction, check valves are employed in the vast majority of industrial processes. At DFT® Inc., we provide a wide range of check valves for use in diverse industrial applications. Our spring-assisted in-line check valves, for instance, are specifically designed to prevent water hammer by eliminating the risk of reverse flow. And, if sizing is done to account for flow rather than line size, these high-performance valves will operate reliably and efficiently for years, without the need for extensive maintenance.

In-Line Check Valves

The experts at DFT® often help clients assess their unique check valve requirements; our check valve sizing program allows us to easily determine required valve sizes before actual setup, eliminating the risk of design errors and delays. DFT® check valves can be installed in-line in any orientation; valve operation will not be hampered in any way by the specific orientation chosen, provided the flow direction is in line with the valve design (as indicated by an arrow on the valve casting).

However, for a downward flow, these check valves need to be modified slightly to support the additional weight of the disc and any static head that may be involved. While silent check valves can be employed in vertical piping or in installations requiring constant controllable pressure, swing valves should only be used in horizontal pipe runs, in which minor flow variations are expected.

When using swing check valves, users are afforded limited pressure control, as there is less control over valve opening and closing. Therefore, this type of valve is usually employed in less sensitive, large-scale pipelines carrying liquids, gases, or steam. To allow for enhanced performance, these swing check valves can be replaced by our GLC® Silent Check Valves or Excalibur® Silent Check Valves. These silent check valves have only one moving part and allow for greater flow variability than a conventional style swing check valve. Also, because the DFT Axial Flow Check Valves have so few moving components, they are more resistant to wear and tear and can maintain a longer lifespan.

However, the GLC® model is not considered a “dead-end” service valve. It is essential that the upstream, or seat end, of the valve be connected to the line until the pressure is relieved from the downstream end. The seat end of the valve must always remain bolted to the mating flange when the valve is exposed to downstream pressure in order to avoid possible blowout of the internals, as the retaining screws do not account for direct exposure to downstream pressure. In addition to eliminating water hammer, appropriately sized silent check valves can greatly improve system safety, protect critical system components like pumps, and improve overall system life while reducing maintenance costs.

Learn More

DFT® check valves are specially designed to improve the efficiency and safety of your industrial processes, and our team of experts is ready to assist in identifying the ideal model for your specific needs.

To learn more about our valve solutions, and why it may be beneficial to replace your current valves with DFT® non-slam check valves, download our new eBook, “Non-Slam Check Valves vs. Swing Check Valves.”

Steam Condensate: Important Things to Know

In our latest webinar, we provide an engaging, informative overview of steam condensate and its critical role in industry today. The webinar includes a short history of steam condensate, some of the most common problems that arise when utilizing it, solutions to those problems, and a survey of its many modern applications.

The History of Steam Condensate

The history section of our webinar discusses the origins of steam research, beginning with Thomas Savery, who invented the first steam engine in England at the end of the 17th century. He developed and patented it for use in pumping wells in 1698. Thomas Newcomen would later refine that invention in 1712, adding water tanks and pump rods so that deeper water mines could be accessed with steam power. In 1778, James Watt further built on these discoveries, employing a gearing system that allowed a steam engine to drive a flywheel in order to produce rotational power, spurring the development of the steam locomotive. These inventions, all originating in England, would become the catalyst for the Industrial Revolution and shape the world as we know it today, with steam power playing an instrumental role in a wide range of industries — including mining, chemical processing, petroleum production, textiles, pulp and paper production, and, most importantly, power generation.

The Basics of Steam Condensate

The webinar then describes the basics of steam condensate, answering the question: Why steam? The main advantages of steam stem from its high efficiency and ease of transportation and control, which make it an ideal medium for heat transfer. Steam power is easy to create due to the abundance of water and wide range of heating options available; simply by managing the temperature and pressure of steam, it can be used for much of the work that powers the industrial world. The three biggest users of stream power today are the power generation, pulp and paper manufacturing, and chemical processing industries; in these sectors, steam is used for all manner of jobs, including automation, dilution, fractionation, quenching, mechanical drive, and stripping.

Common Issues With Steam Condensate

There are some challenges involved in using steam condensate, however. For instance, it’s important to maintain high-quality steam in order to prevent a variety of pipe and valve issues, as low-quality steam can reduce heat-transfer efficiency by as much as 65%. Also, if CO2 combines with steam condensate, the formation of carbonic acid and CO2 gas may occur, which can cause rapid corrosion. Luckily, this can be managed through the use of steam traps, which keep water separated from the steam. Engineers and plant managers must also consider the line sizing of pipes in order to prevent condensate collection, as well as the location and configuration of equipment, the insulation methods used, and the types and quality of different valves used for different applications.

Steam Condensate Q&A

Below, we’ll delve into some of the most common questions we receive regarding steam condensate.

- Q: Do you propose using traps for all piping loops with low points in offsite piping?

- A: Yes. The condensate must be removed from the lines in order to prevent water hammer or corrosion of the piping itself.

- Q: Can you share some guidelines for specifying cracking pressure? Is there a tool one can use?

- A: It’s best to work with directly a manufacturer to pinpoint the best low cracking pressure options for your specific application. In-line (silent) check valves typically have a cracking pressure of approximately 0.5 psi. Depending on the condensate return piping layout, a standard cracking pressure (CP) valve may allow excess condensate to accumulate. In these scenarios, a lower CP is ideal; options will vary from manufacturer to manufacturer. At DFT, we offer solutions that allow for a CP as low as 0.1 psi.

- Q: Are there any formulas or tables available for steam pipe sizing?

- A: We recommend the reference handbook, “Crane Technical Paper No. 410.”

- Q: Are low cracking pressure check valves only necessary in certain types of steam systems?

- A: Low cracking pressure valves should be used for condensate return lines, not main steam lines. Also, low CP valves will help reduce the accumulated condensate in return lines.

Learn More

All of these matters and more are discussed in our comprehensive online webinar and its accompanying slides. To learn more about steam condensate, view DFT’s prerecorded webinar today.

Valve Value: The Return on Investment (ROI) of Quality Check Valves

Fluid system management requires a complete approach; if any component is compromised from the pump to valve to pipe and back again, flow can suffer. In-line management, including products such as check valves, can be challenging — after all, they can be a major purchase. However, the lifespan, safety, and efficiency of your system require careful investment.

Not all check valves function or cost the same. A check valve’s long-term return on investment (ROI) is a major factor and can be significantly more important than upfront cost of these components.

Assessing Real Cost and System Lifespan

Putting a system’s needs in perspective requires factoring in the unfortunate possibility of worst case scenarios and highest demands. In evaluating your component needs, remember to factor in:

- Maintenance

The cost of maintenance can be high in time, money, and human resources, especially if parts need to be regularly maintained. - Down Time

The worst case scenario for production managers — system failure — demands necessary valve repair or replacement. The resulting downtime comes at a high cost to an entire facility. - Media Demands

Do you handle a highly acidic or caustic application? You may require a higher-grade alloy than standard 304 or 316 SS (stainless steel) for chemical resistance and system component lifespan extension. - Water Hammer Problems

Sometimes a side note in engineering, water hammer can cause serious damage to piping, valves, and pumps, resulting in unwanted shutdowns. Custom sizing your valves and using DFT silent check valves can help manage water hammer issues.

The Real ROI: High Performance Check Valves for Optimal System Performance

At their most basic level, check valves are smart components designed to allow fluid to flow in one direction and prevent back flow in the other. They are self-automated, driven by pressure as opposed to an operator.

On the surface, it would appear that the more complex the check valve, the higher the price tag —but is that an accurate conclusion?

Bearing in mind the considerations above, our value experts take ROI seriously. In a study evaluating the performance of swing check valves versus the more high-tech axial flow silent check valves over a 20 year period, we found that the utility facility had a significant savings over time using axial flow silent check valves.

Comparing initial cost of components to lifespan, the system’s superior performance using axial flow silent check valves reduced annual maintenance costs. In fact, the valves worked so well that they led to an 85% reduction in overall operating costs at the facility!

Making a Case for High Quality Components

The utility facility our team tracked is far from the only example in the field. Real world applications abound, reinforcing the idea that high quality check valves can lead to superior performance. Our value team has found that better-made, sophisticated components offer reduced maintenance expenses, long lifespans, and reliable valve and fluid system performance in countless cases, including:

- A United States chemical facility struggling with a water hammer. They replaced worn out, double door check valves with three 10”, 150/300# ALC check valves and completely eliminated the problem — their system has been running smoothly since 2012.

- A food processing facility that has relied on the DFT SCV Check Valve since the 1950’s for sanitizing management. It met safety needs and industry criteria as a leading technology then and now.

- A petrochemical plant with high cycling and system failures. They replaced failing swing check valves with the DFT model GLC Check Valves, custom-sized for the application. DFT valves minimized the chattering and excessive cycling previously disrupting the system.

Investing with Smart Components at DFT

Do you want to prevent check valve failures but have concerns about cost? Our check valve experts and value team are here to help you with sound engineering and upfront investment evaluations. Reach out to contact an expert today, and we’ll guide you through the best valve solutions to fit both your application and your budget.

Customizing Your Condensate Line Check Valve for Low Cracking Pressures

Understanding Low Cracking Pressure in Condensate Lines

O ne of the most common issues in steam systems is the pooling of steam condensate — a byproduct of all steam processes — inside of the equipment. When released from a high-pressure area to a low-pressure area, pooled condensate can flash, or quickly heat back up into steam, resulting in extreme pressure spikes, audible banging noises, valve and steam line failure, and even full equipment failure.

ne of the most common issues in steam systems is the pooling of steam condensate — a byproduct of all steam processes — inside of the equipment. When released from a high-pressure area to a low-pressure area, pooled condensate can flash, or quickly heat back up into steam, resulting in extreme pressure spikes, audible banging noises, valve and steam line failure, and even full equipment failure.

To mitigate these risks, manufacturers in the chemical processing industry incorporate steam traps and condensate drain systems into their equipment. These applications also utilize in-line check valves in the condensate system piping to allow flow in only one direction — from low pressure to high pressure — before sealing.

Cracking pressure, or the minimum upstream pressure at which the valve can operate, is a critical aspect of check valve applications. To help manufacturers ensure they use the best components for their processing system, check valves can be designed and specified for unique cracking pressures.

Customizing Your Condensate Line Check Valve

There are a few key considerations to keep in mind when selecting check valves for steam applications. Important factors include:

- Sealing ability

- Resiliency — Resilient, reliable seals will provide a long-lasting, leak-tight seal through the use of engineered elastomers; these seals are highly resistant to abrasion and are mainly used for low-pressure environments (up to 500 psig).

- Metal-to-metal — More reliable for piping systems with temperature and pressure changes, metal-to-metal seals are able to withstand higher contact forces and pressures (exceeding 500 psig).

- Non-slam characteristics — The valve must be able to close quickly to prevent the reverse flow that can result from steam condensate flashing. Factors that influence non-slam characteristics include:

- Disc location in the full open position

- Length of stroke to close

- Presence of a closure mechanism, either internal or external to the valve

- Orientation of the valve and piping

To learn more about methods for eliminating steam condensate issues in chemical processing operations, download a copy of our eBook, “The Challenge with Steam Condensate.”

API 6D -24th Edition Certification:

Why it’s Important for Quality and Safety of Your Check Valves

What is the API Q1 ninth edition and API 6D 24th edition monogram specification?

The American Petroleum Institute (API) is a trade association that has led the development of petroleum and petrochemical equipment and operating standards. Its API Monogram Program verifies that manufacturers are operating in compliance with industry standards.

The API Q1 ninth edition specification establishes the API Quality Management System requirements necessary for organizations to consistently and reliably manufacture products in accordance with API or other specifications for the use in the petroleum and natural gas industry.

The API 6D 24th edition specification defines the requirements for the design, manufacturing, assembly, testing, and documentation of valves for application in pipeline and piping systems for the petroleum and natural gas industries.

The API 6D 24th edition specification defines the requirements for the design, manufacturing, assembly, testing, and documentation of valves for application in pipeline and piping systems for the petroleum and natural gas industries.

This API 6D 24th edition specification holds hydrostatic and pneumatic testing to a new higher standard, unlike the less API 598 testing, API 6D testing requires increased pressure testing durations, test medium rust inhibitor injection, medium pH monitoring and more stringent design and manufacturing process control, as well as packaging requirements to reduce valve damage from transportation.

When requested by the purchaser, an API 6D monogram valve manufacturer must meet the strict testing and documentation requirements to insure the valves performance under designed operational pressure and temperature conditions.

Purchasing valves under the specification ensures greater reliability and safety for equipment and personnel.

Download our API 6D Certificate

Common Industries that Require API 6D

When transmitting raw materials and potentially harmful chemicals, it is critical that check valves are tested for proper safety and functionality. Therefore, the API 6D certification is commonly required for valves used in petroleum, natural gas and electrical generation industries. Specific industries requiring API 6D include:

- Natural Gas Transmission: Check valves are frequently built into natural gas transmission pipelines to prevent the occurrence of reverse flow. They act as critical components within these systems, as improper flow could result in dangerous leakages, contamination, explosions, or fires.

- Petroleum Production and Refining: Transforming crude oil into refined products for consumer industries requires a multi-step chemical process that adheres to strict standards. Check valves are used in a range of petroleum-related applications, including discharge compressors, cooling towers, water treatment, pumps, generators, and boilers.

DFT Valves Built to API 6D 24th Edition Standards

In order to meet the needs of our clients in the natural gas and petroleum industries, we have certified our GLC® and PDC® check valve manufacturing processes to meet API 6D 24th Ed. specifications. By improving design, manufacture, assembly, testing, and documentation processes, we’re able to provide a higher level of quality and safety.

- GLC® Silent Check Valve: This silent center-guided, spring-assisted flange valve can be used with several types of fluids and can operate under a wide range of temperature and pressure combinations. This check valve is API 6D 24th certified and available in various materials and sizes.

- PDC® Check Valve: A silent, non-slam valve that is specifically designed to allow gases to flow in one direction through a pulse-dampening chamber on the discharge side of a compressor. Our PDC® model is API 6D 24th certified and available in a range of materials and sizes.

- DFT is in the process of adding other valve models to the list of API 6D 24th certified valves. Contact DFT if you require API 6D 24th Edition Certification.

Online Case Studies

To learn more about how DFT’s API 6D certified check valves perform across industries, check out our application success stories.