Category Archive: Check Valves

DFT Releases Efficient New Axial-Flow Check Valve

DFT Inc., an industry leader in the manufacturing of check valves for more than 70 years, proudly announces the release of its new BNC™ Check Valve, a nozzle-style, axial-flow check valve specifically designed to excel in high-pressure applications.

Many natural gas companies and other industries are now placing their pipelines below ground and are looking for a one-piece valve they can weld in and bury. The BNC™ Check Valve answers that demand with a precision nozzle-style valve that uses axial-flow technology to eliminate turbulence and prevent erosion and vibration. This design reduces downtime and maintenance costs and boosts capacity and accuracy.

Additionally, this valve provides a critical service to the power industry because the valve’s one piece body eliminates leak paths, while providing tight shut off.

This valve is a spring-assisted, center-guided, non-slam check valve. It has an in-line globe-style body with butt weld ends, with the seat integral to the valve body.

The one-piece valve is designed for long life and a no maintenance required design.

The design meets ASME B16.34, and its testing meets MSS SP-61 and API 598 (shell and seat). The valve is available in 10″ to 24″ line sizes, and it is constructed of A216-grade WCB carbon steel and other alloys per ASME 16.34 by request.

Trim materials are carbon steel and stainless steel with a hard-faced seat and disc. The valve can be installed either horizontally or vertically and is compatible with steam, water, and gaseous media. Custom sizing for the BNC™ Check Valve is available.

ABOUT DFT INC.

DFT Inc. manufactures severe service control valves and in-line check valves in its Exton, Pennsylvania, facility. DFT takes pride in working closely with end users to solve problems. The results are valves that provide superior performance, long service life, and low maintenance costs.

Meet the PDC Valve, DFT’s Unique Check Valve

Industry professionals responsible for proper fluid and gas flow are well aware of the importance of check valves. Since many check valves operate automatically and are not under constant human control, choosing the right type of valve is critical.

Every application demands a unique valve; this is particularly true when referring to the discharge side of reciprocating air or gas compressors. Reciprocating compressors, also known as piston compressors, are used in a variety of industrial applications, including:

- Oil refineries

- Gas pipelines

- Chemical and natural gas processing plants

- Refrigeration plants

- Building maintenance

- Mining

- Power generation

- Primary metals

- Pulp & paper

- Textiles

Reciprocating compressors produce high levels of pressure in order to move gases, so any check valve utilized in this process must be extremely durable and reliable.

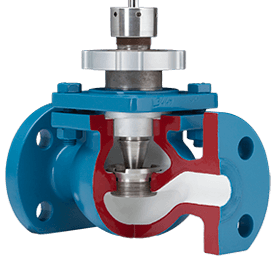

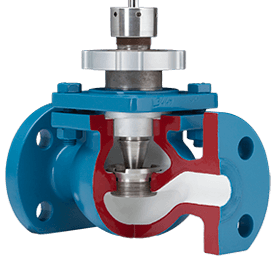

At DFT, our team designs, manufactures, and distributes an assortment of check valves to suit even the harshest applications. In order to handle the demands of discharging reciprocating compressors, we have created the unique DFT® Model PDC® Silent Check Valve.

The PDC® valve is a nozzle-style, spring-loaded check valve that allows gases to flow in only one direction. The PDC® valve offers users a variety of benefits; perhaps its most significant feature is its unique pulse damping chamber. The valve’s pulse damping chamber helps maintain the disc in the open position during momentary reductions in flow, which are directly associated with each cycle of a reciprocating compressor. Pulse damping will also protect against costly premature seat wear.

No matter your company’s needs, DFT offers a PDC® Silent Check Valve to fit any application. Our selection of 59 different PDC® Silent Check Valves includes:

- Different ASME classes (150 RF, 300 RF, 600 RF, 900 RF, 1500 RF)

- Various sizes (2”-DN 50; 3”-DN 80; 4”-DN 100; 6”-DN 150; 8”-DN 200; 10”-DN 250; 12”-DN 300)

- Dimension A (9.5-44.5”/ 241-1130mm)*

- Dimension B (6”-26.5”/152mm-673mm)*

- Cracking Pressures of 0.35 psig/0.024 bar-0.82 psig/0.057 bar

- A216 Grade WCB, A352 LCC, A351 CF8M body materials

*Larger sizes available via factory consultation.

The PDC Silent Check Valve meets several industry standards, including ASME B16.10 (for face-to-face dimensions).

If you need to rely on reciprocating compressors, then the DFT® Model PDC® Silent Check Valve might be the ideal choice for you. To learn more about this one-of-a-kind product, visit our resource library or contact a DFT representative today.

Pressure Testing DFT Check Valves

Check valves are known for their versatility and durability in diverse applications and processes. Many professionals rely on check valves daily, and as such, the valves they utilize must be of the highest possible quality.

Moreover, check valves must conform to industry standards to ensure successful results. DFT Inc. has manufactured check valves for over 70 years; our team of specialists fully understands the stringent demands of any application. One of our main goals is to prevent check valve failures before they occur—that’s why each DFT valve is thoroughly pressure and leak tested.

Moreover, check valves must conform to industry standards to ensure successful results. DFT Inc. has manufactured check valves for over 70 years; our team of specialists fully understands the stringent demands of any application. One of our main goals is to prevent check valve failures before they occur—that’s why each DFT valve is thoroughly pressure and leak tested.

Test Methods

DFT check valves are subject to MSS SP-61, an ANSI standard that institutes the requirements and acceptance criteria for shell and seat closure pressure testing. Proper pressure testing is conducted through various methods.

Shell Test

Valves are tested at a gage pressure no less than 1 ½ times the 100º F rating, rounded to the next highest 25 psi increment. The test medium is water, and the test should not be less than:

- 15 seconds for valves sized 2” and less

- 60 seconds for valves sized 2 ½” to 6”

- 120 seconds for valves sized 8” to 12”

- 300 seconds for valves sized 14” and above

Results: During the test, no observable leakage is allowed.

Seat Test with Water

Valves are tested at a pressure no less than 1.1 times the 100º F rating. The test medium is water, and the test should not be less than:

- 15 seconds for valves sized 2” and less

- 30 seconds for valves sized 2 ½” to 8”

- 60 seconds for valves sized 10” to 18”

- 120 seconds for valves sized 20” and above

Results: For metal seated valves, maximum allowable leakage is equal to 40 ml/hr of water per every inch of nominal valve size. For soft seated valves, no observable leakage is allowed.

After one hour, the maximum allowable leakage is 80 ml for 2” valves, 240 ml for 6” valves, 560 ml for 14” valves, and 800 ml for 20” valves.

Seat Test with Air

DFT valve models SCV®, Basic Check®, Vacuum Breaker, and Restrictor Check® are tested at an air pressure of no less than 80 psig. The test should not be less than:

- 15 seconds for valves sized 2” and less

- 30 seconds for valves sized 3”

Results: For metal seated valves, the allowable leakage is 0.4 SCFH/inch of inlet size. For soft seated valves, no observable leakage is allowed.

Keep Our Test Info on File

DFT Inc.has created a Valve Leak Test Infographic so you can access these pressure tests in an easy-to-read file. The infographic illustrates the types of tests performed by DFT, as well as the standards to which we hold our valves.

To learn more about our specialized testing methods, please contact us today.

Once Upon a Time This Valve Worked Well

Our process had to be shut down again. It seems that the original valve is no longer up to the task. Should I continue to simply repair the valve or should I look for another solution? Up until now, it was far easier to repair the valve and/or replace it in kind … but my process efficiencies are going down and I need to find a solution. Where do I start?

Changing Conditions

I pull out the valve data sheet and take a look at the original conditions. Wow! I can see immediately that things have changed –

- The plant has aged nearly 20 years;

- We replaced the pump on that line 5 years ago;

- We have modified the piping in the area of the valve;

- We changed the fluid chemistry;

- Instead of operating continuously, the plant is now cycling

Every time conditions change, we need to review the impact upon the control system.

Aging Systems

As a system ages, it does not get any cleaner. Whether it is due to pipe scale or there is other sediment in the system, a valve that worked in a clean system may not work as well in the older system. We have periodically been pulling the valve with cage style trim in order to drill open the passages. We have also noticed that the valve trim is wearing out more quickly. The valve simply requires more maintenance.

New Pump

Installing a new pump can change how the system operates. A new pump generally means that we have a new pump curve to work with. The new pump curve means that the flows and pressures have changed from the original specification.

Modified Piping

We added a new branch line. A closer look reveals (I use my 20D2 rule of thumb) that the new line may have lowered the flow rate through the control valve. Is it possible that the control valve is no longer properly sized? The trim in an oversized control valve erodes more quickly than the trim in a properly sized valve. Alternately, if the valve is undersized, I may be seeing high velocity erosion which also negatively affects trim life.

Changing Chemistry

Although we have always maintained our chemistry within recommended boundaries, we can see that our targets have changed over the years. Newer technology allows us to more closely hit the mark. Is it possible that this has tipped the balance and we are now seeing erosion-corrosion in the valve since the originally specified materials are no longer noble enough?

Cycling vs. Base Loading

When we changed from a base loading operation to a cycling operation, we started to strain our control valves. Now they operate more frequently and often work in the low end of the range. By changing the operation, I now need to have a valve that is suitable for severe service when previously I could use a standard valve.

The DFT HI-100™ control valve can be a good choice when conditions change. It deals well with dirty fluid, can be sized properly for the new conditions, is not subject to erosion corrosion and is designed to perform well in the most severe services.

The Importance of Good Information About Valves

Proper valve selection is critical for ideal operation of any system. Improper valve selection can cause system underperformance or failure. The greatest problem when selecting valves is incorrect information.

Often, we may only have access to incomplete or dated information regarding valve applications. Do we know enough about the system the valve will be used in or the main purpose of its use? This “bad information” can create a situation where the theoretical situation does not match reality.

Good Information is Key

“Bad information” comes in many forms. Original design specs might be difficult to obtain, and having those specs does not guarantee success. Occasionally, specs aren’t properly updated. Information that was good at first can fail to incorporate changes in process conditions. If the actual pressure, temperature, flow-rates or the media is different than that which was used to select the valve, it may fail or fail to work properly.

“Bad information” comes in many forms. Original design specs might be difficult to obtain, and having those specs does not guarantee success. Occasionally, specs aren’t properly updated. Information that was good at first can fail to incorporate changes in process conditions. If the actual pressure, temperature, flow-rates or the media is different than that which was used to select the valve, it may fail or fail to work properly.

When choosing a gate, globe, ball or check valve, we always want the valve to be operating in the full open or closed position. Control valve selection, however, targets 40% to 60% open for normal flows. When most control valves operate below 20% open or over 80% open, they can lose their ability to control properly.

What information is required to properly size a valve? Fluid type, operating pressures and temperatures upstream and downstream of the valve, and the flow rates associated with these conditions are required information to have.

Knowing What is the Right Valve for the Application

There are many different types of valves available. They do not all work the same way or for the same purposes. Each valve type has its advantages and disadvantages.

For proper control valve selection, it is important to understand how the valve is used to control system flow. For example: is the system tuned for a constant set point, or is it set to modulate a variable flow over time? The layout of the piping system and locations of reducers and elbows also impact valve performance.

Often, choosing what seems to be the most efficient valve might not be the best valve for application. Replacing a valve “in kind” with an upgraded version of an older valve might actually do more harm than good.

Poor Performance – Get Good Information

Unfortunately, the blame for poor performance often lands on the installed valve when it is actually bad information that caused its failure. Simply repeating the bad information to select a different valve is doomed to have the same results. When DFT Inc. is asked to troubleshoot an installation, we start by collecting all of the available information and check for “bad information” concerning flow conditions and application mismatches with respect to the installed valves.

Take the time to get good information. Fortunately, the information is more readily available today than it has been in the past through trending information. If you can provide actual system operational information, your chance for success increases significantly.