Category Archive: Check Valves

Watch DFT Valves’ ALC® Axial Flow Check Valve in Action

Check valves are instrumental for regulating fluid flow within a given valve system. When properly chosen and installed, check valves are meant to operate seamlessly throughout their design life; improper check valves can lead to harmful complications—such as water hammer.

Water hammer is one of the most common problems befalling check valves. Simply put, water hammer is the generation of shock waves that occur when a liquid comes to a sudden stop inside a pipe. These high-pressure shock waves persist until the energy of the surge dissipates; during that time, shock waves can cause serious damage to pipe lines, joint gaskets, pressure gauges, and other components.

Valves that close on reversing flow and back pressure are major contributors of water hammer; these valves include swing check valves, tilting discs checks, and double door check valves. Water hammer can lead to poor productivity due to failures, so it’s vital to use check valves designed to combat this issue.

DFT Valves’ ALC® axial flow check valves are an ideal choice to reduce the effects of water hammer. The DFT Valves team created a short video to demonstrate how beneficial this check valve can be to your system.

DFT Axial Flow vs. Double Door Check Valve

In this video, we demonstrate the difference between our ALC® check valve and a double door check valve on the psi of a pump valve application. This specific application is 15 psi, and the double door valve causes a pressure spike that nearly reaches 60 psi. Due to this pressure imbalance, we replaced the double door valve with our axial flow check valve.

Once the ALC® check valve is installed, you can immediately notice the pressure stabilize within the pump’s system. The psi goes from zero, back up to 15 without any pressure spike as the ALC® valve cycles.

Benefits of the ALC® Check Valve

The DFT ALC® valve is designed specifically to prevent water hammer and reverse flow. Lightweight and compact, these valves can fit between mating flanges with ease. ALC® valves are useful for a variety of applications that involve liquids, gases, or vapors. Other benefits of these valves include:

- Simple to maintain

- Can be installed horizontally or vertically

- Body material can be carbon, stainless steel, or other materials.

- Custom sizes can be made to your specifications

- Meets several industry codes and standards, including ANSI, MSS, and ASTM

To learn more about choosing a DFT check valve that is best suited for your application, contact us today.

The Importance of Accurate Check Valve Sizing

Check valves are among a system’s essential components. For greatest efficiency and maximum protection, however, check valves must be properly sized in order to work at their highest level.

A properly sized check valve will make a system reliable and provide the longest service with the minimal amount of manual attention. Proper sizing will eliminate disc fluttering whether the valve’s disc is in the stable and fully open position against the internal stop, or in the fully closed position against the seat.

Properly sized check valves also contribute to overall cost savings. Appropriate sizing increases the lifespan of the valves, but also improves the longevity of pumps and other related components on the same system. Check valves that are sized correctly function well, and in the process enhance the safety of processes and applications.

Examples of Check Valves

There are a variety of types and styles of check valves. These are applied to a number of processes.

- Ball checks: Ball checks control the movement of flow by using a “ball” inside the body. The ball can freely rotate, resulting in a wearing and wiping action that is suited very well to handle viscous materials. Ball checks can also be spring-loaded to safely lock a system.

- Dual plate: Dual plate valves are made of two spring-loaded semicircular plates with a hinge in the center. These valves are known for their excellent flow capacity, due to their lightweight nature and compact face-to-face dimensions. Their compact size means they need less manual attention, support, and valuable real estate in a system.

- Piston Check: Piston check valves feature a body-guided or stem-guided disc that operates within the body bore. This ensures that the disc and seat are properly aligned when the valve closes. They are available in T pattern and Y pattern body designs. The latter usually have a higher flow coefficient than T pattern bodies.

- Swing Check and Tilting Disc: Swing check valves or tilting disc valves are designed with a hinged arm at the top of the valves. Gravity and reverse flow are the chief mechanisms responsible for closing this valve. These valves come with a variety of connections, such as socket weld, flanged, threaded, ring type joint or butt weld end connections.

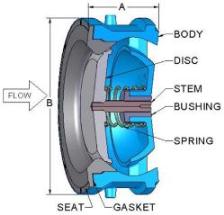

- Spring Assisted In-Line/Axial Flow Check: These valves are also sometimes referred to as Nozzle Check or Silent Check Valves. Their primary design function is to prevent reverse flow and reduce or even eliminate water hammer. The mechanism behind this is a spring-assisted disc, constructed in line with the flow with a short travel distance, which acts as a fast-closing valve. These valves can be installed in any position, with either vertical or horizontal pipe runs, and is available with a number of different styles and end configurations.

Correct Sizing Means Best Fluid Handling

Before purchasing valves, be sure to consider a number of factors that go with it, chief among them proper sizing. Properly sized valves will prevent malfunctions and ensure that a system operates reliably and efficiently. All related system components will last longer and safety—both for the workers and the valves—will be enhanced.

Check valves play a central role in fluid handling systems, and it is crucial to ensure that they are properly sized. Consulting a qualified professional and carefully considering your options will help you choose the best check valve, and ultimately help your bottom line. The best valve choice gets you the most out of your systems and equipment for the longest possible and most efficient performance.

Design Elements to Consider when Selecting a Check Valve

Check valves perform a crucial function in pumping systems by permitting the forward flow of water when open, and preventing reverse flow when shut. When selecting a valve for your water and wastewater pumping system, you will likely want one that not only executes this task, but also does so efficiently.

Check valves should minimize energy consumption and also protect the system from pressure surges caused by water hammer. They should also suit your particular application. The two common types of check valves to examine are silent or in line check valves and swing check valves.

3 Common Problems in Check Valve Selection

Did you know that, unlike other types of valves, check valves continue to work if a plant loses electricity, air, manpower, or all of the above? They come in a wide variety of sizes, materials, and end connections, and can be used in countless applications.

So why is it that they’re often improperly sized or selected? It’s because check valves are only as good as their application. Oftentimes the problems with a check valve are not related to the valve itself, but application and other factors. So when you’re problem solving or replacing a check valve, keep these three common problems in mind:

Water Hammer

Water hammer is one of the most common check valve problems. Water hammer is a pressure surge that’s caused when a liquid or gas is forced to stop or change direction suddenly, and often occurs when a valve is suddenly closed at the end of a pipeline system. This can result in both noise and vibration, which can in turn lead to damage and additional maintenance or repair costs.

Water hammer can be prevented, however, by using a faster-closing check valve that stops the pressure surges and shock waves that can damage and rupture equipment. Our silent check valves in particular are known for their effectiveness in preventing and in many cases eliminating water hammer.

Reverse Flow

Reverse flow is another common check valve problem and can be extremely costly, especially when it occurs at the discharge of a pump, causing the pump to spin backwards.

Is Your Check Valve Oversized for Your Application?

In a recent blog post, we discussed some of the common check valve problems, and the fact that many of them are not related to the valve itself, but with the selection and/or application of the valve.

One of these problems is oversizing that can lead to a host of problems. Such issues include excess pressure that will wear out the valve and lead to extensive maintenance costs or early replacement needs. This is because the flutter, caused by vibration and/or instability, will rapidly damage the valve.

The Cause of Valve Oversizing

Often, people will size a check valve based on the pipe diameter, which is what leads to oversizing. Not only does this create performance issues, but it means you’re overpaying for a valve much larger than you need. Initial costs and ongoing maintenance costs increase as a result.

Therefore, the rule of thumb is: size your check valve for the application. This will ensure that no fluttering of the disc occurs, and will provide the longest valve lifespan. When a check valve is sized the way an on/off valve is sized, it ignores the fact that the flow conditions of a check valve determine its internal performance.