Category Archive: Uncategorized

Using DFT Check Valve to Solve High Flow Lockout in Combustion Turbine

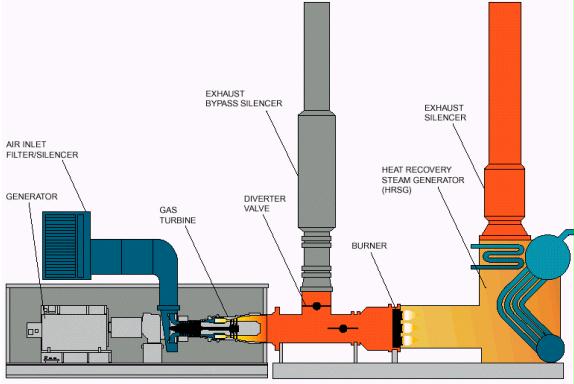

There was a case study done at a power company regarding the installation of the check valve developed by DFT Inc. near the combustion turbine. The GLC Check Valve developed by DFT is connected on Low NOx Dual Fuel Turbines. The combustion turbines can run using diesel fuel or natural gas. When the turbine is fuelled by diesel, water is injected into the diesel in order to increase its power and lower the emission.

A 3” 600# water injection line goes into the turbine. At the turbine, the line is further split into 20 – ¾” lines that are spread out equally around the turbine.

Natural Gas Dilemma

The turbines, as mentioned earlier, can also run using natural gas. However using natural gas requires that the power company must ask for permission from a local gas company in order to fuel the turbines. The problem when using natural gas is that the turbines consume so much that gas companies would need to run their compressor station at max capacity. Failure to do so might affect their downstream customers. When this scenario happens, the turbine combustion is forced to rely on diesel fuels.

High Flow Lockout

Another problem that might occur is the High Flow Lockout. This happens when one of the 20 – ¾” check valves malfunctions, allowing air to go to the isolation valve, which in turn, causes the turbine to fail.

It is hard to pinpoint which of the 20 smaller valves have malfunctioned, requiring the operator to inspect each of the 20 valves individually.

The power company wants to remote start the turbine within 15 minutes of its cold start state. In this case, the only way for it to start quickly, is to utilize diesel fuel.

Solution with DFT Check Valves

The solution to all these problems is the installation of the DFT check valves. The 3” 600# 316SS GLC with soft, seat, sizing and a special spring, was installed on the water injection line near the turbine.

By doing so, the possibility of air backing up in the isolation valve is eliminated. The turbines can now work efficiently, whether using natural gas or diesel fuel.

The installation of the DFT check valves has been in the system for 6 years now, and no failure in the turbine has occurred. Word of the successful solution has spread to other plants resulting in the installation of DFT silent check valves.

DFT Model PDC® Solves Air Compressor Problems

Inside their control valve test and research facility, a major valve manufacturer was using two reciprocating air compressors that were designed to run until the stored air pressure in the extremely large volume tanks reached a set point.

They would then shut off for anywhere from several minutes to several hours, depending on demand. During the shut-off intervals, the wafer-style swing check valves on the discharge side were leaking, tripping the relief valves and threatening to over pressurize system components.

The Use of DFT Technology

On several occasions, the continual pounding of the valve seats resulted in total failure, which caused the system to blow the intermediate stage safety relief valve and totally shut down.

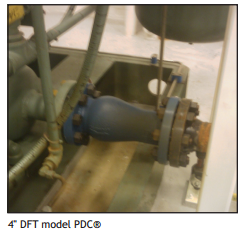

Despite being a valve manufacturer themselves, they recognized that our insight into check valve technology would help them find the best way to address shut-off performance and longevity. Our solution was to replace the valves in both the 200 hp/1000 psig and 400 hp/400 psig air compressors with DFT model PDC® check valves.

Preventing System Pressure from Bleeding Back

Designed specifically for reciprocating equipment, these silent, non-slam check valves prevented system pressures from bleeding back into the compressor when the machines were off as well eliminated the unacceptable reverse flow leakage. The machines now run in optimal states and are no longer susceptible to shut down.

If you are interested in learning more about this project, or if you have a situation that would benefit from our insight into valve technologies, contact us today.

Consequences of and Solutions to Water Hammer

Water hammer is a phenomenon that can be either a mild nuisance or a severe problem. It is usually considered a safety hazard. The extreme pressure caused by water hammer can blow out gaskets and cause pipes to suddenly rupture, causing serious injury to anyone nearby.

Identifying Water Hammer

Usually, you can identify water hammer by a loud banging or hammering sound coming from pipes, especially after quickly shutting off a water source. This sound is caused by the pressure shockwave hitting some kind of blockage like a closed valve or joint at a high force. The noise can sometimes be deafening, and can sometimes become a major source of stress, especially for any nearby workers.

Damage Caused by Water Hammer

Recurring cases of water hammer, however, are more than just an annoyance. Water hammer can cause serious damage to pipelines, pipe joins gaskets, and all other components of the system like flow meters and pressure gauges. On contact, these pressure spikes can easily exceed five to ten times the working pressure of the system, placing a tremendous amount of stress on the system.

Water hammer can also cause leaks at the joints in the system, crack pipe walls and deform piping support systems. It can be quite expensive to repair or replace damaged pipeline components and equipment. Worse, the cost can grow exponentially if the spill results in an environmental issue.

Solutions to Water Hammer

Water hammer can be prevented or reduced in a number of ways, depending on its cause. Educating and training operators is one of the simplest ways to minimize water hammer caused by hydraulic shock. Training allows operators to learn the importance of properly opening and closing manual or actuated valves, and can take care to minimize the effects of water hammer. Operators can also be more careful in safely opening and closing quarter turn valves like ball valves, butterfly valves, and plug valves.

Another option of reducing the pressure spikes caused by water hammer are water hammer arrestors. Water hammer resistors are components of the piping system that reduce the noise and stress to pipeline systems by absorbing the shock. Just make sure to size and install them properly, otherwise they will not be as effective.

Valves Can Reduce Water Hammer

You can also install check valves in vertical pipe lines. These include swing checks, tilting discs, and double door check valves, all of which can be made to operate in a vertical line. Keep in mind that these will not prevent reversing flow in this orientation, in which case a Silent Check Valve is the best option.

Sometimes the sudden closure of swing check, tilting disc and double door check valves can cause hydraulic shock. You can prevent this by changing these valves with silent of non-slam check valves, such as the kind manufactured by DFT. Rather than reversing flow, silent check valves close when the differential pressure across the closure member of the valve decreases.

Water hammer can be caused when valves slam shut; silent check valves are far less likely to cause this to happen. The valve fully closes when the differential pressure across the disc approaches the cracking pressure of the valve. The fluid then decelerates and decreases momentum before the valve is fully shut. This also ensures that the fluid does not reverse direction.

The Growing Success—and Increasing Needs—of American Oil and Gas

By now it should come as no surprise that American manufacturing is back, and all signs point to full speed ahead. There are many reasons for this, and one of them is our country’s natural gas boom—an abundance of production and supply that’s helping to make manufacturing here more cost effective and competitive.

In fact, the Energy Information Administration recently reported that “soaring shale production” resulted in 2013 seeing the fastest growth rate ever for oil production.* Articles such as this one confirm this, pointing out that America should be completely self sufficient in oil production by 2037—meaning zero imports and enough domestic production to support the entire country’s energy needs.

DFT Inc. Hits the Airwaves with Net Worth and Terry Bradshaw

Many people know Terry Bradshaw as a football player, and from his antics as part of Fox’s Sunday broadcast team. A growing number are learning about, if not his serious side, at least a side of him that isn’t all fun and games.

As host of the television program Net Worth, Bradshaw has been letting America in on a not-so-well-kept secret: that aside from his on-the-field and in-the-studio accomplishments, he is also a savvy, sharp businessman. Fun fact: he may have planted that seed as a used-car salesman – while he was still playing football. Imagine if that were LeSean McCoy’s offseason job!

Net Worth showcases the most creative, the most successful, and just the best in business across a wide range of industries. For these reasons, we were incredibly proud when DFT Inc. was asked to be featured in a segment in 2013. The Net Worth show featured DFT’s exclusive Canadian distributor Triangle Fluid Controls , or TFC. We view this segment and DFT’s inclusion on Net Worth as both humbling as well as a signal that we’re doing something right in our quest to provide the best products and service in check valves.