Why Do DFT® Axial Flow Check Valves Inherently Reduce Water Hammer?

Comments Off on Why Do DFT® Axial Flow Check Valves Inherently Reduce Water Hammer?Hydraulic shock—more commonly known as “water hammer”—occurs when the flow within a pipe is suddenly forced to change direction, which creates a pressure wave that can be characterized by a loud knocking or banging sound. In piping and process systems, water hammer often happens upon closing a valve to stop or redirect flow. It’s important to take steps that will reduce water hammer or mitigate its effects, as repeated waves of pressure can cause significant wear on pipes and joints over time. Even without wear, a strong enough pressure wave may still burst weak threads or seals.

The best way to stop water hammer is to bring the flow to a stop before it reverses direction. This may be achieved using a valve, but the valve in question must be able to respond very quickly to the change in flow rate through the piping system. In this blog post, we will examine why the DFT® Axial Flow Check Valve is the best choice to halt water hammer of the 3 most common types of check valves:

- Swing check valves

- Double-door check valves

- Axial flow check valves

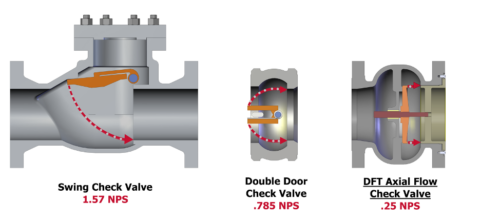

The time it takes for a valve to go from full open to full closed relies heavily on the distance the disc must travel. If the valve must respond quickly, it stands to reason that a shorter distance can be traversed in less time. The following illustration compares the travel distance for the above valve types.

To simplify the explanation, we’ll use nominal pipe size (NPS) to represent the inside diameter (ID) of the pipe in all examples in this blog.

How Swing Check Valves Close

Swing check valves contain a disc that is hinged above the ID of the pipe, so the distance the swing check disc travels is ¼ of the circumference of the circle, where the radius of the circle is the NPS. If circumference is πD, then ¼ of this would be πNPS/4 or 1.57 NPS.

How Double-Door Check Valves Close

The disc used in a double-door valve is comprised of two halves hinged along the split. Each half of the disc travels through an arc, which can be represented by ½ NPS. Therefore, the distance that each half of the double-door disc travels is half the distance of the full disc in the swing check, or πD/8 or 0.785 NPS

How DFT® Axial Flow Check Valves Close

In general, axial flow check valve discs travel ¼ NPS (0.25 NPS) from a fully open position to a fully closed position. Given that a swing check valve disc must travel almost six times that distance to close, it stands to reason that an axial flow check valve disc can close much faster. By adding a spring to the disc, the disc can close before the flow reverses to avoid the water hammer effect.

Preventing Water Hammer With DFT® Axial Flow Check Valves

Water hammer poses a risk in most piping and process piping systems. Without proper solutions in place to mitigate hydraulic shock, these systems are at risk of bursts, leaks, or excess long-term wear. This makes it especially important to use check valves that can reverse flow without creating a damaging hydraulic pressure wave. To do this, the disc within a check valve must be able to close as quickly as possible.

DFT® Axial Flow Check Valves are designed with fast closure in mind. The spring-loaded discs in these valves go from fully open to fully closed with a significantly shorter travel distance than other check valve types. With this short distance and fast closure capabilities, the overall valve closure time is significantly reduced. This naturally mitigates the risk of water hammer.

For more information about our check valves and how they can prevent water hammer in your system, please request a quote.