What Is Cracking Pressure?

Comments Off on What Is Cracking Pressure?What Is Check Valve Cracking Pressure?

Cracking pressure refers to the inlet pressure level at which the first sign of flow is present. It can also be described as a measure of the pressure differential between the inlet and outlet ports of the valve when flow is initially detected. Specifically, cracking pressure is the least differential pressure that the valve experiences during flow.

Check valves are frequently used with liquids, but they are also found in many industrial applications handling media such as steam, gas, slurries, and mixed-phase flows. In relation to cracking pressure, pressure drop is another, somewhat related aspect of pressures within a valve to keep in mind. Pressure drop is the difference in pressure between both the valve’s inlet and outlet. Once the cracking pressure is reached, the valve starts to open, which facilitates the flow of the contained media. As the flow rate decreases, the valve then starts to shut.

The cracking pressure will depend on the check valve design. It’s usually measured in pounds per square inch (psi), pounds per square inch gauge (psig), bar or kPa (their metric equivalents), or both.

Why Is Understanding Cracking Pressure Important?

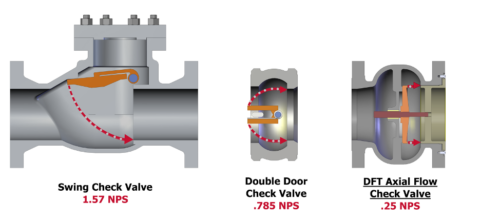

When choosing a check valve for a particular application, it’s important to know the valve’s cracking pressure. This specification is the initial indication of flow, but the valve won’t be fully open when it reaches cracking pressure. You’ll need to select the most appropriate valve with the right internal component design to achieve the required cracking pressure and overall pressure differential.

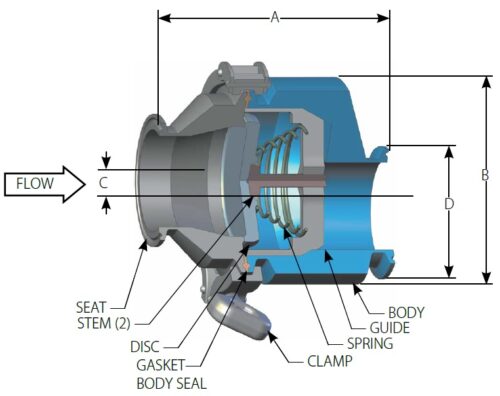

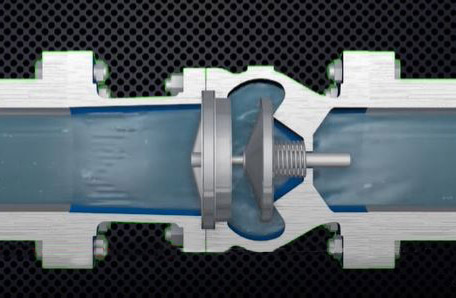

It’s also important to keep in mind that a check valve is designed to control flow in only one direction and is available with a specific normal cracking pressure. As the fluid flows through the valve and the pressure becomes greater than the cracking pressure, the disc moves off the seat, and the valve opens compressing the spring. When a check valve is oversized for the expected flow, it creates low flow (low velocity) conditions. Changing the spring to a lower cracking pressure can be one way to reduce chattering while improving the stability of the valve.

What Happens When the Incorrect Cracking Pressure is Selected?

Cracking pressure can have a significant impact on the compatibility of a check valve with its intended application. Certain issues can occur if the cracking pressure is too high or too low.

- Too high. High cracking pressure causes a higher pressure drop across the check valve. If the cracking pressure is too high, the valve may not open fully or at all. When the check valve isn’t fully open throughout normal flow, it may pop or chatter, which can lead to premature wear.

- Too low. Low cracking pressure can reduce the valve’s closing speed. If the cracking pressure is too low, the valve may also be unable to close entirely in the vertical flow down position because of the stem and disc weight overcoming the opposing force of the spring.

Get Check Valves with the Correct Cracking Pressure at DFT®

To ensure consistent flow and avoid premature wear, it’s important to choose the right check valve for your specific application. If you need help finding the correct check valve with the right specifications, DFT® carries a wide variety of check valve products to meet your application’s requirements. We offer a selection of threaded/socket weld check valves, vacuum breaker check valves, restrictor check valves, sanitary check valves, and more.

For help finding a check valve with the right cracking pressure for your needs, contact us today or request a quote to start your order.