Case Study: The ROI of Reliable DFT Valves

In order to efficiently and reliably withstand wear, pressure, and damage, critical system components such as check valves must have excellent durability.

Unfortunately, quality and durability are often sidelined or overlooked in favor of low upfront costs. While the desire to keep costs low is understandable — everyone has a bottom line to look after — the return on investment (ROI) of quality products drastically outweighs the long-term costs of lesser-quality, low-cost parts.

Below, we’ll take a look at a case study illustrating this concept.

Cooling Towers Case Study- DFT Check Valves long-lasting for over 24 years

Cooling towers are integral components in a variety of industrial and manufacturing processes; electric power generation plants are one of the most common and recognizable applications.

Serving as heat-rejection devices, cooling towers transfer process-generated heat from a system into the atmosphere. Open- or closed-circuit water systems pick up heat throughout the system; in the tower itself, the lower temperature of the atmosphere cools the water, usually by allowing a degree of evaporation.

Cooling towers require very complex water — and, occasionally, steam — piping systems.

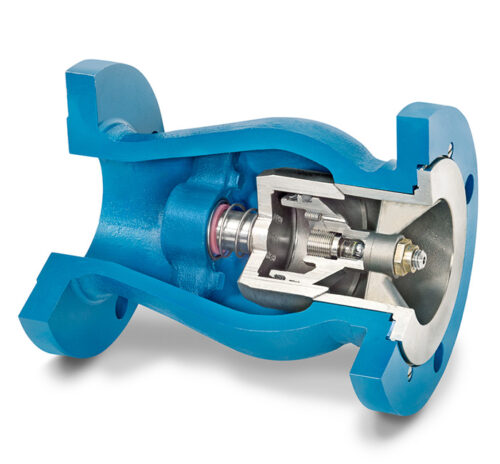

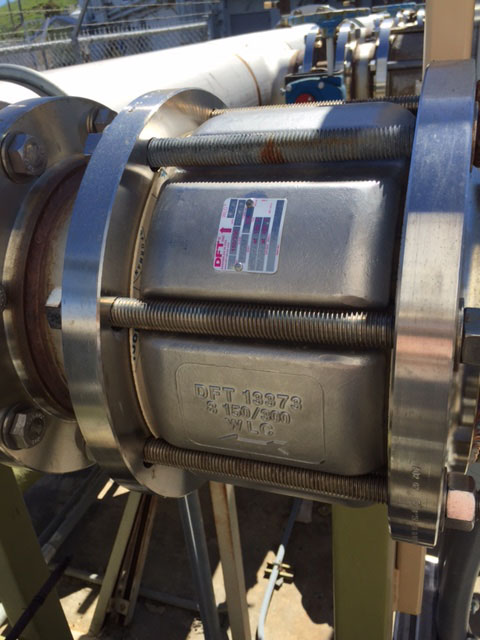

One of DFT®’s clients, based in California, has a number of functioning cooling towers. In 1993, this client replaced 24 check valves in the piping system of a cooling tower with axial flow check silent check valves from DFT®.

In the intervening 24 years, only one of those valves required replacement — in 2017. The remaining 23 DFT® check valves from 1993 remain in good working order, allowing this client significant cost savings.

The ROI of Investing in Reliable Equipment Upfront

Plant managers from various industries often believe complex valve products — axial flow silent check valves, for example — are prohibitively expensive based on the initial price tag, without considering the long-term costs involved in valve maintenance and replacement.

A utility facility recently concluded a 20-year ROI study using DFT® check valves and found significant savings and ROI of quality check valves. The study compared valve costs and associated overhead, including administrative, installation, and shipping costs, for 150# and 300# valve classes. Swing check valves were used for a 10-year period, followed by a 10-year period using DFT® axial flow silent check valves.

While administrative costs for both types of valves were the same, in this case comparison silent check valves from DFT® had initial higher cost. However, a significant difference was seen as the the 150# swing check valves were failing at a high rate, required replacement more than four times each year, at a cost of $111,000 over the tested decade; the DFT® silent check valves required replacement only once every three years, at a cost of only $16,600. The 300# swing check valves showed similar results, while the 300# DFT silent check valves never needed replacement over the decade, reducing replacement and maintenance costs to zero.

Learn More

The inital prices for these high-quality axial flow silent check valves may seem prohibitive at first but these complex products have been carefully engineered and manufactured from top-of-the-line materials, ensuring optimal performance and reliability.

And when maintenance and replacement costs are included in the purchasing decision, it becomes clear that higher-quality check valves are a much more cost-effective option. For the clients discussed above, the use of quality DFT® check valves saved between 85% and 100% of valve-related maintenance costs over time.

DFT® check valves are made to last, designed for durability and superior sealing. Need to keep your systems leak-free and operational for the long run? Contact the team today, and a check valve expert will be in touch to discuss your options.