DFT® Silent Check Valves

Silent check valves, also known as non-slam check valves and spring-assisted check valves reduce or eliminate water hammer and its effects.

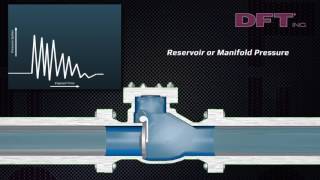

Water hammer refers to the high-pressure shock waves that occur when the flow of fluid abruptly stops (due to pump shut down or a valve disc quickly closing) in a piping system. When water hammer occurs, the resulting flow reversal places severe stress on the pipe, endangering its structural integrity, and opening it to potential rupture and damage. Swing check valves, tilting disc check valves, and double door check valves, among others, often contribute to water hammer problems.

To control water hammer and reverse flow, the use of silent check valves is recommended. When the source moving the fluid shuts down and the forward flow of the fluid decreases, the specially designed stainless steel spring action of the silent check valve controls the valve disc closure to occur prior to flow reversal. This spring assist insures that the valve does not slam shut, and the occurrence of water hammer is eliminated.

Product Selection

DFT’s full line of spring-assisted check valves can be custom sized based on requirements for a specific application, and can be used in both horizontal and vertical liquid, gas, or steam installations.

DFT offers a wide range of silent check valves, including:

- Flanged check valves

- Wafer check valves

- Threaded check valves

- Vacuum breaker check valves

- Restrictor check valves

- Sanitary check valves

The wafer style DFT Model ALC® Axial Flow Check Valve is a silent check valve designed specifically to prevent water hammer and reverse flow. This lightweight and compact nozzle check valve meets API 594 Face-to-Face dimensions to fit between mating flanges with ease and can be used in a large variety of applications and industries involving liquids, gases, and vapors.

Design Features & Benefits

Because they were designed with one specific purpose in mind – preventing water hammer – DFT’s silent check valves are known worldwide for their effectiveness in preventing reverse flow and water hammer-related problems. Moreover, our silent check valves are designed to start opening at approximately 0.5 PSI differential pressure, with full opening occurring at 1.0 PSI differential pressure.

In addition, DFT’s silent check valves feature the following characteristics:

- Fully meet MSS SP 126-2000 Steel In-Line Spring-Assisted Center Guided Check Valves Standards

- Available with soft seats for bubble-tight shutoff

- Can be used in liquid, gas, or steam applications

- Allows smoother fluid flow, and responsive opening and closing without the sudden movements that cause water hammer

Applications

DFT’s silent check valves are recommended for commercial and industrial applications

They are ideal for use in horizontal and vertical installations in liquid, gas, or steam applications.

Industries that use our check valves include:

- Building maintenance

- Chemical processing

- Energy

- Gas transmission

- Government

- Mining

- Oil & Gas

- Paper/pulp

- Primary metals

- Research/testing

- Textiles

- Water treatment

Learn More

Since 1943, DFT® has been respected globally for our “non-slam” check valves. We also understand that standard solutions don’t always meet the needs of extreme applications, so our team of experts is standing by to help you tailor a valve solution that fits your specific operation. To learn more about our nozzle style silent check valves, or other valve products, contact our team, or download our Check Valves catalog.