Gas Check Valves | Gas Transmission

With millions of people worldwide depending on gas for commercial and residential energy needs, the gas transmission industry is critical to modern life. Gas transmission systems consist of a complex network of compressor stations, distribution pipelines, storage facilities, and more. Check valves are an integral component of gas transmission systems, preventing reverse flow, dangerous gas mixtures, and the risk of pulsating pressures. Improper gas flow can lead to potentially dangerous problems such as leaks, contamination, shutdowns, fires, and explosions.

Check valves from DFT® are engineered to address the challenges of the gas transmission industry, such as pulsating compressor discharge and low-pressure applications. Learn more about the different types of gas transmission check valves we offer to select the best product for your application.

Selecting the Best Gas Check Valve Type

The gas transmission industry has strict requirements, so DFT® offers various types of check valves with different end connections for numerous applications. To determine the ideal gas check valve for a gas line application, users must understand the types of valves and their respective industry standards. They must also address the unique requirements for each project, such as pressure, temperature, and environmental conditions to ensure the gas transmission system’s reliability, safety, and efficiency.

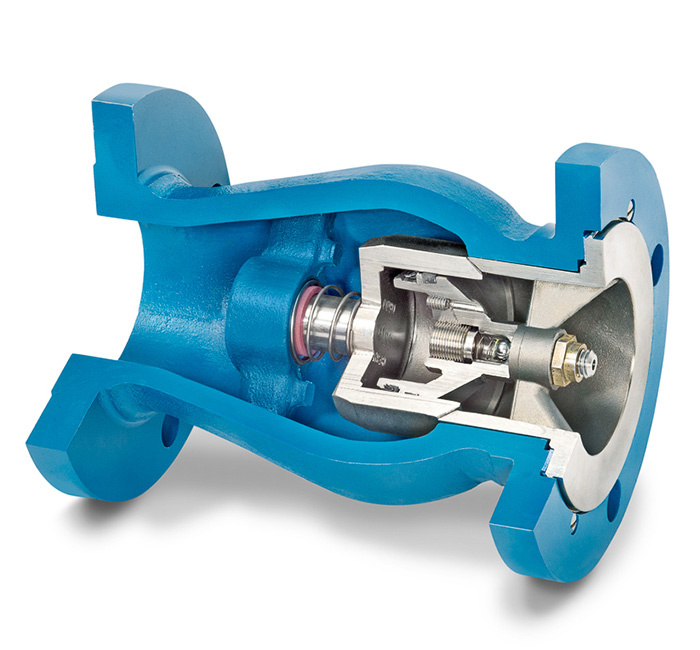

Flanged Check Valves

Flanged check valves are constructed with a flange on each end of the valve, allowing for direct attachment to flange fittings for a secure connection within the pipeline. The user can bolt the valve directly between the flanges for a reliable and stable connection in various industrial applications. Flanged check valves are common within petrochemical plants, oil and gas processing plants, and other gas transmission applications. Flanged check valves from DFT® include:

PDC® Flanged Check Valve: This valve can be installed on the discharge side of reciprocating gas or air compressors. The pulse damping chamber maintains an open disc position during momentary flow reductions in each reciprocating compressor cycle and protects the valve seat from excessive wear.

DLC® Flanged Check Valve: The DLC® is an economical, spring-assisted in-line check valve available in sizes ½” through 3”, offering versatility, dependability, and corrosion resistance with an Inconel® X-750 standard spring and stainless steel construction.

Excalibur® Flanged Check Valve: The Excalibur® is an in-line check valve with a spring-assisted and center-guided design to deliver reliable and low maintenance service for various fluids at a range of pressures and temperatures. We offer various material compositions, sizes, pressure ratings, and a butt weld end option for numerous applications.

GLC® Flanged Check Valve: The GLC® is a flanged check valve with spring assistance and center guidance, offering low-maintenance, reliable service for various fluids in a range of sizes, temperatures, and pressures. The valve offers non-slam, silent operation with minimal pressure loss.

Threaded Check Valves

Threaded check valves have a threaded connection, allowing for a convenient and secure connection directly to threaded fittings or pipes. The threaded end is screwed onto a matching thread, making installation and replacement simple in applications where flanged or welded gas line check valves may be impractical. Threaded check valves have a small footprint, making them ideal for compact gas transmission and piping systems that require quick and simple installation.

Threaded check valves from DFT® include the following:

SCV® Threaded In-Line Check Valve: This spring-assisted valve offers non-slam operation, versatility, reliability, and corrosion resistance in various applications. It prevents water hammer and delivers tight shutoff with a long-lasting stainless steel construction.

Basic-Check® Threaded In-Line Check Valve: This valve provides non-slam, reliable, and low-maintenance operation in various steam, liquid, and gas applications. It provides metal-to-metal sealing with a precision-lapped disc and seat to deliver tight shutoff. For bubble-tight shutoff, the valve can be fitted with optional soft seats.

Vacuum Breaker Threaded In-Line Check Valve: The valve prevents pressure vessel or tank collapse. It also prevents condensate backup during equipment shutdowns. The Vacuum Breaker valve dampens water hammer with the addition of air on the downstream side, breaks siphons, and prevents piping collapse in the event of transient pressure drops.

Restrictor Threaded In-Line Check Valve: This versatile, spring-assisted valve is suitable for higher cracking pressure applications from 2 up to 40 PSI. It can be used with different pipe fittings like drain elbows and couplings to create a full check valve unit.

SCV-R® In-Line Restrictor Check Valve: The SCV-R® is a self-contained valve for higher cracking pressure applications than the standard SCV® and installs directly on the pipeline.

Wafer Check Valves

Wafer check valves have a space-saving flangeless design that fits compactly between flanges. Secured with bolts, wafer check valves are ideal for confined spaces. As a result, they are commonly found in gas transmission systems. Wafer check valves from DFT® include:

ALC® Wafer Check Valve: The ALC® is a center-guided, spring-assisted wafer check valve that prevents slamming, reverse flow, and water hammer. It is light and compact and meets API 594 face-to-face dimension requirements.

FBC® Insert Wafer Check Valve: This is a spring-assisted, lightweight, compact, and easy-to-install valve that prevents slamming, water hammer, and reverse flow. Like the Basic-Check® valve, the FBC® offers metal-to-metal sealing with a precision lapped disc and seat for tight shutoff. A resilient soft seat option can provide bubble-tight shutoff if needed.

WLC® Wafer Check Valve: The WLC® is a low-maintenance, lightweight, center-guided, spring-assisted valve that offers non-slam operation in various fluid systems at a range of temperatures and pressures. A flange gasket is installed between the seat ring and body to provide a tight seal and prevent leakage during service.

TLW® Wafer Check Valves: The TLW® Wafer Check Valve is a lugged pattern wafer check valve, designed for settings where exposed studs are unsuitable. This spring-assisted, center-guided wafer check valve meets API 594 face-to-face dimensions and prevents reverse flow and water hammer.

View Product Catalog Contact Us

Common Check Valve Applications in the Gas Transmission Industry

Check valves support many gas transmission applications—one of which is compressor discharge. Reciprocating compressors are commonly used to efficiently move gas over long distances through pipelines. This flow must only go in one direction; reverse flow cannot be allowed. Check valves are designed into pipeline systems to eliminate reverse flow.

Because of the pulsating pressure inherent in reciprocating compressors, specially designed pulse-dampening check valves are often used to reduce wear in the valve and dramatically improve reliability.

Other check valve applications in this industry include metering pumps, hydraulic lines, air lines, pump discharge, compressor inlet and discharge, and pressure letdown.

Meeting Gas Transmission Industry Standards

DFT® designs and manufactures check valves that meet the strict requirements of the gas transmission industry. Our check valves comply with major industry standards. To demonstrate our commitment to delivering high-quality, reliable valve solutions, we maintain these certifications.

Contact Our Experts for Premium Gas Check Valve Solutions

DFT® offers various gas check valve types for the gas transmission industry, including flanged, threaded, and wafer check valves. We are committed to meeting industry standards with quality one-way gas valves for the gas transmission industry. Download your free copy of the DFT® Check Valve Catalog. Contact us or request a quote to speak with a specialist about the right valve for your application.