Semiconductor Valves

Semiconductors are vital to the operation of everything from computers and consumer electronics to missiles and aerospace components. To produce these highly sensitive chips and ensure their integrity, semiconductor fabrication facilities — or fabs — rely on high-purity, ultra-clean environments and process fluids to avoid product contamination.

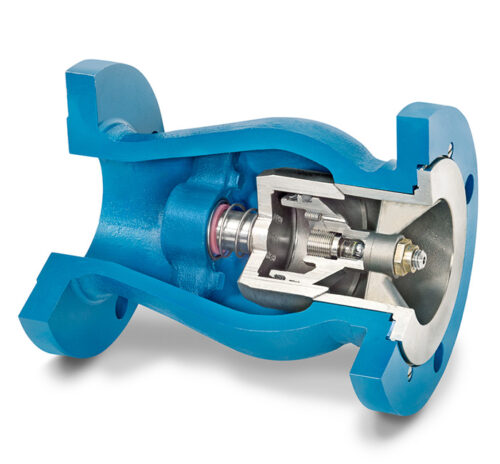

Fabs utilize extremely high volumes of water as well as steam in semiconductor manufacturing applications, and check valves are responsible for backflow prevention by creating a tight seal in fluid systems for the industry. Found on the discharge of a pump, these unidirectional valves facilitate process fluid flow but prevent gases and liquids from flowing backward. Were a check valve to fail, water could reverse-spin the pump impeller, damaging the pump.

DFT® Inc. has spent over 80 years manufacturing high-quality check valves and building long-standing partnerships with industry giants in the semiconductor field. To support clients in semiconductor manufacturing and fabrication, we’ve developed high-performance semiconductor check valves that mitigate the risk of equipment damage, pressure drop, water hammer, and backflow for reliably clean operations.

High-Quality Semiconductor Check Valves From DFT®

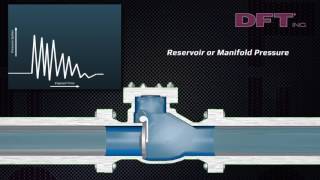

When a pump shuts down or a valve abruptly closes, water hammer is the pressure surge pipes can experience when fluid within the system suddenly comes to a full stop or alters direction. That impact force can generate pressure surges exceeding ten times the system’s working pressure, harming pipes, valves, and pumps or introducing contaminants into pure water supplies. Your system may develop leaks or ruptured pipes, ultimately resulting in system failure and property or asset damage.

Addressing these challenges, our ASME Class 150 to 1500 WLC® Wafer Check Valves are well suited to the semiconductor manufacturing market. They reliably supply a smooth, uninterrupted flow of water while mitigating the effects of water hammer to ensure streamlined semiconductor production and minimize downtime related to equipment damage.

They’re designed to handle a wide range of fluids as well as temperature and pressure combinations. These lightweight, low-maintenance wafer valves feature a center-guided/dual-guided stem and are available in RF or RTJ ends.

Their axial flow design enables them to deliver nonturbulent process fluid flow with low pressure drop for superior performance. Also, these products offer non-slam spring-assisted silent closing, designed to safeguard against water hammer and backflow thanks to their reliable closing mechanism with fast response time. As process fluid flow slows or halts, the valve’s spring seats its internal disc before water hammer, backflow, or pressure spikes can occur.

This is particularly applicable to semiconductor manufacturing as avoiding contamination, maintenance, or downtime is paramount. The spring-assisted closing function supports contamination management, equipment and fab protection, and overall process stability.

Have Questions? Speak With a Valve Specialist

Benefits of DFT® Check Valves for Semiconductor Manufacturing

Semiconductor valves from DFT® deliver a leak-tight seal to eliminate the risk of contaminating process gases and liquids. We maintain an extensive inventory of our standard check valves to offer you ready-to-ship solutions with fast turnaround. However, we also understand that many applications benefit from custom-engineered components. With DFT®, you have the option to custom size to your specific application, choose material of construction, flow rate, and pressure rating of our engineered products.

Proper sizing is essential to valve longevity. As part of our proprietary sizing program, our team can manufacture semiconductor valves in large sizes — up to 12 inches in some cases. We also utilize high-quality, ultra-clean metal options like stainless steel, titanium, Hastelloy®, and specific metallurgies for enhanced corrosion resistance against harsh chemicals. Unlike swing check valves, you can install our valves horizontally and vertically-flow up or flow down.

We manufacture check valves with an emphasis on quality you can trust. This starts with procuring high-quality materials from certified partners. As an ISO 9001:2015-certified company, DFT® focuses on quality assurance during production. Finally, each of our valves is hydrostatically tested for leakage rate and, as part of our commitment to product integrity, we offer a one-year warranty from the date of installation, or 18 months from the date of purchase.

Semiconductor Applications of Check Valves

Check valves are advantageous in numerous semiconductor industry applications, such as:

- Producing ultra-pure water

- Rinsing

- Cooling

- Etching

- Handling wastewater

- Operating cooling towers

- Running recirculation pumps

- Managing water input to cleanroom (WICR) systems

Essentially, where there’s a pump, there’s a check valve.

Selection Considerations for Semiconductor Valves

To ensure you select the right valve for your application, it’s important to first consider:

- Compatibility of the valve’s material composition with your application’s process chemicals

- Specifications for pressure and flow rate

- Piping system limitations on weight and size to ensure proper system installation

- Maintenance requirements to support continued, reliable performance

- Expected life cycle for long-term reliability

Unsure about valve choice? Reach out to a sales representative in your area. We excel at hands-on problem-solving and deliver exceptional continuity of service, as many of our knowledgeable sales and engineering team members have been with DFT® for decades.

Partner With DFT® for High-Performance Semiconductor Check Valves

For optimal protection against contamination, reverse flow, equipment damage, and more in your fluid systems, semiconductor check valves from DFT® are a reliable, lasting solution. Contact us for more information on our engineered check valves, or request a quote today.