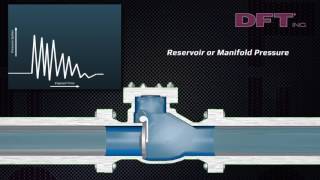

The Effects Of Water Hammer

To some it’s just the character of an old house–that loud clanging noise when you shut the water off. In this way, it can be easy to ignore or write off as nothing. Don’t–this is a sign of water hammer.

The first clue WH is present in a plumbing system is a single or series of bangs, followed by echos after shutting off a water source. Normally, water flows through pipes in a constant manner that’s not arresting in nature. So, it can be pretty obvious there is a problem present that needs attention.

What Is The Outcome Of Water Hammer

A few considerations when dealing with fluid hammer include pipe size, valve closure rate, and water velocity. In terms of pipe size, the shorter the pipe is, the faster the water can flow smoothly.

If a longer pipe is introduced, water hammer can start being an issue. When a valve closes quickly, it creates a shockwave effect for the water in the pipe. Its velocity is too rapidly halted and the water crashes within the system, creating an audible banging sound.

Similarly, if the water itself is running very quickly, a valve closure will again cause this shockwave effect.

So, now you know you probably have this problem upon hearing the indicative noise, and need to do some investigating. The pressure caused by the abrupt stoppage is what can cause system failures, among other problems mentioned.

Understanding the pressure within your system can help you to find the problem, and therefore solution to your WH issues. Traditional math is a tried and true way of figuring out just how much pressure is building up when the valve is closed.

Use the following formula to find the pressure involved: P=(.07)(V)(L)/t + P1 where P=pressure increase, P1=inlet pressure, V=flow velocity in feet per second, L=upstream pipe length in feet, and t=valve closing time in seconds.

To use this formula, you’ll gather the needed data to solve for P. Here’s an example: Where you have a 40 foot long upstream pipe, a valve closure time of 48 ms, a recommended PVC piping velocity of 5 ft per second, and 50 psi inlet pressure, solve for P to get 331.67 psi.

With the recommended maximum pressure for a house at about 80 psi, you can see how our scenario in the formula is well above a safe level. It can also help you adjust the components to adjust the pressure to a more acceptable level. If you lack the information to use this formula, invest in a pressure gauge from your local hardware store.

Now that you’re aware of the problem and by how much it needs to be alleviated, there are a few solutions to consider. Newer piping should include air chambers, or cushions, to compress the possible shockwave of water.

Older systems that already have these chambers may just need a cleaning to solve this problem. If chambers are filled with residue or waterlogged, they will not be effective in prevention of the problem. In this case, simply clean the piping. If pipes don’t have chambers at all, install a pressure-reducing valve in the supply line or reduce the water pressure.