Water Hammer In Your Building

Have you ever shut off the water in your building and heard a loud banging noise? This may be caused by water hammer, a common plumbing problem that is relatively easy to solve.

Caused by the rapid pressure introduced in a pipe, water hammer begins with either a valve closing suddenly or a pump abruptly shutting down.

If this happens when the valve is opened, it is important to keep in mind that it could also be indicative of air in the pipes, either in addition to water hammer or as the main source of the problem.

Water hammer, however, is most commonly found upon closing a valve — the larger the line size, the more pronounced the problem can become.

Getting To The Source Of The Water Hammer Problem In Your Building

After identifying possible causes of the water hammer, pinpoint the source of the problem by considering pipe size and length. It is also important to be aware of high velocities within the piping system, which are caused when large volumes of water flow through smaller diameter lines.

Velocities above 5 feet per second (or 1.5 meters per second) are not only potentially noisy, but are much more likely to cause water hammer when any valves are closed.

Once you’ve assessed the length and size of the pipes in question, examine the stoppage rate, or the time it takes to close off any shut-off valves. Quarter turn valves, like automated Ball Valves and Butterfly Valves, run the risk of closing too quickly.

Understanding how quickly the flow of water is stopped after a valve closure can prove essential to identifying the issue at hand, so be sure to find out how long it takes for the valve in question to close.

How To Solve The Problem

Finally, the rate at which water flows also affects the occurrence of water hammer. Fast-moving water causes more significant water hammer, so a reduction in water velocity may help to solve the problem.

While details for addressing this problem will depend on the specific system and valves used, this solution typically involves re-piping to a larger diameter or using a pressure regulator to decrease pressure.

To address the problem of excess water flow, there are a few potential solutions. First, new piping can be designed to include air chambers, or cushions, to dissipate the possible shockwave of water. In older systems that already have these chambers, it could be a matter of simply cleaning or servicing. Once the chambers are waterlogged or filled with residue, they will no longer serve their purpose.

If cleaning out chambers is not a possible solution for your piping scenario, or if your pipes do not have chambers, reducing the water pressure or installing a pressure-reducing valve in your supply line may prove a helpful solution.

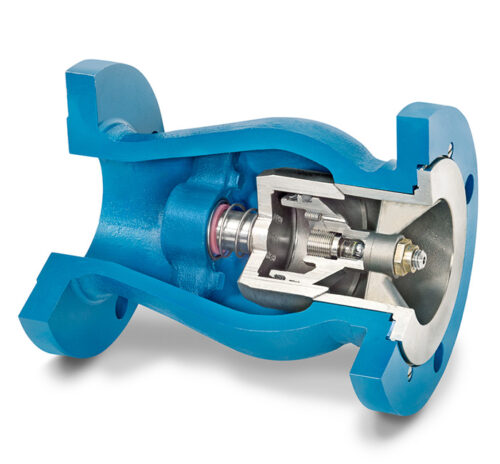

Alternatively, installing In-Line or Silent Check Valves in any vertical pipe runs can serve as a replacement for swing check or other styles of check valves. Vertical piping on the discharge side of a pump is notorious for causing water hammer. While swing check valves are not recommended in these installations, Silent Check Valves are recommended and work very well.