Valve Selection Chart

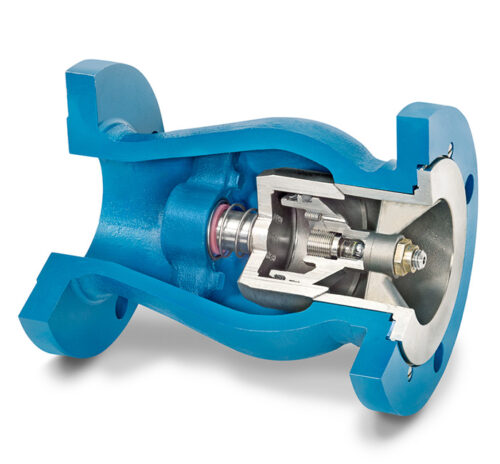

DFT® offers a full range of check valve sizes designed to work with a variety of fluids, including liquids (including fines or slurries), air, steam, condensate and various other gases.

We’ve assembled this comprehensive chart to help you choose the appropriate DFT® check valve for your specifications. If you would like to learn more about our range of valve selections or tailor customized solution for your needs, don’t hesitate to contact us today.

| THREADED VALVES | FLANGED VALVES | SANITARY VALVES | WAFER VALVES | IN-LINE REPAIRABLE VALVES | BUTT WELD | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Basic-Check® | Restrictor Check | SCV® | SCV-R® | Vacuum Breaker | DLC® | Excalibur® | GLC® | GLC®-CAST IRON | PDC® | DSV® | ALC®/TLW® | FBC® | WLC® | WLC®-CAST IRON | Y−CALIBUR® | BNCTM | |

| PAGE | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32-34 | 36 | 38 | 40 | 42 | 44 |

| SIZE | 1/4 to 2-1/2 | 1/4 to 2-1/2 | 1/2 to 3 | 1/2 to 2 | 1 to 4 (OD) |

1/2 to 3 | 2 to 24 | 1 to 42 | 2-1/2 to 42 | 2 to 26 | 1/2 to 4 | 2 to 24 | 1 to 4 | 1 to 10 | 2 to 10 | 4 to 14 | 2 to 24 |

| ENDS | |||||||||||||||||

| NPT | X | X | X(1) | X(1) | X | ||||||||||||

| SW | X(1) | X(1) | |||||||||||||||

| FLG | X | X | X | X | X | ||||||||||||

| RTJ | X | X | X | X | |||||||||||||

| BW | X | X | X | ||||||||||||||

| FLG/BW | X | ||||||||||||||||

| Victaulic® | X | ||||||||||||||||

| Wafer | X | X | X | X | |||||||||||||

| Clamped | X | ||||||||||||||||

| ASME CLASS | |||||||||||||||||

| 125 | X | X | |||||||||||||||

| 150 | X | X | X | X | X | X | X | X | |||||||||

| 250 | X | X | |||||||||||||||

| 300 | X | X | X | X | X | X | X | X | |||||||||

| 600 | X | X | X | X(7) | X | X | X | ||||||||||

| 900 | X | X | X | X(7) | X | X | X | ||||||||||

| 1500 | X | X | X | X(7) | X | X | X | ||||||||||

| 2500 | X | X | X | ||||||||||||||

| 750 CWP | X | X | |||||||||||||||

| 3600 CWP | X | ||||||||||||||||

| OTHER | X(2) | X(2) | X(2) | X(3) | X(2) | X(3) | |||||||||||

| MATERIALS | BODY/TRIM | ||||||||||||||||

| Cast Iron | X(4) | X(4) | |||||||||||||||

| WCB/316 SS* | X | X | X | X | X | X | X | ||||||||||

| 316 SS/316 SS* | X(5) | X(5) | X | X | X(5) | X | X | X | X | X(5) | X | X | X | X | |||

| Other Alloys | X | X | X | X | X | X | X | X | X | ||||||||

| OPTIONS | |||||||||||||||||

| Soft Seat | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | ||

| X-750 Spring | X | X | X(6) | X(6) | X | X(6) | X | X | X | X(6) | X | X | X | X | |||

Notes:

- 1. NPT x SW available.

- 2. CWP RATING BSS, BSA, BSE, BSSV, Restrictor Check: 450 to 2500 CWP

depending on size; BSSH6, BSSV6: 450 to 6000 CWP depending on size.

BSSH7: 800 to 6000 CWP depending on size. DSV: ASME/ANSI Class 108. - 3. API 2000 and 5000 ARE AVAILABLE. Contact DFT for sizes.

- 4. TRIM MATERIAL: BRONZE OR 316 SS

- 5. BODY & SEAT: BSE, BSS, BSSV. Restrictor Check: 303 SS, BSA: 416 SS, BSSH6, BSSH7, BSSV6: 316 SS, DSV:316L SS (A351/CF3M)

- 6. Inconel® X-750 spring is standard.

- 7. Class 600, 900, & 1500 available for TLW only (not available for ALC). * CF8M is the cast grade of 316 SS.

About Valve Selection

Proper valve selection relies on understanding the valve’s function and the setting in which it operates. Issues such as the valve’s intended flow and operating conditions, the direction of operation (horizontal, vertical upward flow, or vertical downward flow), and material compatibility with the intended fluid, all govern which properties your valve should include. The viability of a check valve depends on a number of design factors as well as the design’s suitability within the pumping system in which it will be installed. Evaluating the valve’s end connection, envelope dimensions (especially when replacing an existing valve), and leakage requirements helps narrow down the type of valve required. Certifications such as NSF, NACE, CE mark, and others should also be taken into account. Different check valves have various requirements regarding space, energy, and maintenance. Identifying your application’s specific needs and limitations will help you determine the right type of check valve for your water or wastewater pumping system. Evaluating all these factors will make sure your pumping system does not experience issues such as over- or under pressurization, leakage, and vibration that may require excessive maintenance costs down the line. Download DFT’s Check Valve Data Sheet to assist in collecting your data needed to specify the right check valve for your application.