Water Treatment Check Valves

Water is among the world’s most essential natural resources. Just as it aids in the development of human life and agricultural products, water is utilized to support various industrial processes such as heating, cooling, and sterilization.

The water treatment industry consists of three main segments: wastewater treatment, which removes impurities caused by any industrial process from nearby water supplies; boiler water treatment, which safeguards boiler systems against potentially hazardous chemical substances; and cooling water treatment, which maintains the integrity of recirculating water systems in industrial facilities.

To provide optimal efficiency to industrial processes, water treatment professionals depend on several types of valve products. DFT® provides a variety of easy-to-install, low-maintenance, and cost-effective check valves based on the specific water treatment application.

Types of Check Valves Used in Wastewater and Water Treatment

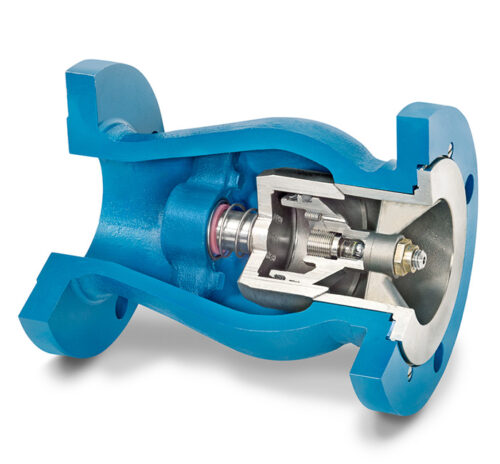

DFT® Inc. offers a comprehensive range of check valves designed to meet the diverse requirements of water treatment applications. Here’s an overview of our water treatment valves:

Wafer Check Valves:

WLC® Cast Iron Body Check Valve: This cast iron check valve is available in 2” to 10” line size and offers non-slam, low-maintenance service, for a wide range of temperatures and pressures.

WLC® Wafer Check Valve: The stainless steel WLC® valve is available in 2” to 10” line size and provides reliable performance for a large range of fluids and temperature/pressure combinations.

ALC® Wafer Check Valve: The ALC® valve is available in 2” to 24” line size that has a compact design that fits between mating flanges. Preventing reverse flow and water hammer, it is a reliable choice for durable, efficient flow control.

FBC® Insert Wafer Check Valve: This insert wafer check available in 1″ thru 4″ line size is designed for minimum space installation across multiple applications. The FBC® valve provides tight shutoff and prevents reverse flow and water hammer.

Threaded Check Valves:

Basic-Check® Threaded In-Line Check Valve: This non-slam threaded in-line check valve is an all-purpose valve with a tight seal built for longevity.

SCV® Threaded In-Line Check Valve: The SCV® threaded in-line check valve is a cost-effective, corrosion-resistant, non-slam valve ideal for a variety of water treatment applications.

SCV-R® In-Line Restrictor Check Valve: This valve is ideal for water treatment systems requiring higher cracking pressures than the SCV® threaded in-line check valve.

Restrictor Threaded In-Line Check Valve: Also designed for higher cracking pressures than the DFT® Basic-check valve, this valve is an all-purpose product that offers low-maintenance service for fluids at various temperature/pressure combinations.

Flanged Check Valves:

DLC® Flanged Check Valve: Versatile, corrosion-resistant, and reliable, the DLC® flanged check valve offers tight shutoff and prevents water hammer.

Excalibur® Flanged Check Valve: The center-guided, spring-assisted check valve offers B16.10 face-to-face dimensions. It is low-maintenance and is available in many pressure ratings and sizes to accommodate your system.

GLC® Flanged Check Valve: The GLC® has a short face-to-face dimension and is available 2” to 26” line size. API 6D availability.

GLC® Cast Iron Body Check Valve: This cast iron valve also has a short face-to-face and provides non-slam, silent operation.

Selecting the Best Check Valve for Water Treatment Applications

Choosing the right industrial water valve for your water treatment system involves several key considerations, such as the proper valve type, end connection, fluid type, flow rate, space available, cost, and more.

Consult with the valve specialists at DFT® for help selecting or custom sizing the right check valve for your water or wastewater application.

Applications in the Water Treatment Industry

Check and control valves are common in water treatment, as these products are utilized to precisely regulate both the flow and pressure of water.

Boiler systems rely on valves for the feeding and discharging of treated water. Valve products are also used to avoid the negative effects of scaling or corrosion within boilers. Additionally, check valves are utilized in cooling towers to prevent the reverse flow of water, which could otherwise lead to critical problems like water hammer and system failure if left unchecked.

Water is integral to several manufacturing processes, and the importance of high-quality check valves resonates throughout the entire water treatment industry.

Our versatile DFT® Check Valves are suitable for both vertical and horizontal installations, addressing the unique needs of the water treatment industry. Whether preventing backflow in filtration systems or ensuring flow control in chemical dosing, DFT® valves offer unparalleled performance.

Download our Wafer Style Axial Flow Check Valve Case Study to learn how our valves helped a specific customer with their wastewater treatment system.

Contact DFT® for Premium Wastewater & Water Treatment Valves

For superior water treatment and wastewater management solutions, turn to the experts at DFT® Inc. Our extensive range of check valves is designed to offer reliability, efficiency, and peace of mind. With our expertise and quality products, you can ensure your water treatment processes run smoothly and effectively.

Contact us or request a quote today to find the perfect valve solution for your needs.